Learn How to Build a Lean-To Shed? with Expert Tips

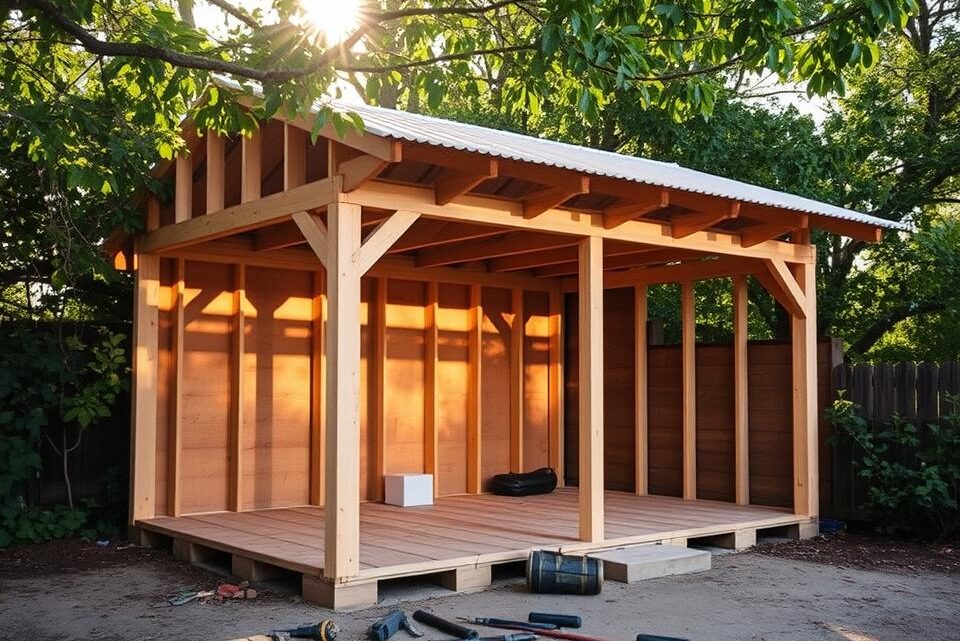

Constructing additional storage space can transform how homeowners utilise their property. A lean-to structure offers a practical solution for those seeking extra room without extensive construction. This guide explores the process of creating one from the ground up.

These versatile structures attach directly to existing buildings, using three new walls. This design makes them more economical and quicker to assemble than freestanding alternatives. Homeowners can customise dimensions and features to meet specific storage needs.

The project suits various applications from garden tool organisation to bicycle storage. Proper planning and accurate measurements are essential for success. Adherence to safety protocols ensures the final structure is both durable and functional.

Inhaltsverzeichnis

Key Takeaways

- A lean-to shed utilises three walls with the fourth side attached to an existing building

- This design offers a cost-effective alternative to prefabricated shed kits

- Customisation of dimensions and features is possible to suit specific requirements

- Proper planning and accurate measurements are crucial for structural integrity

- Considerations for UK climate conditions ensure long-lasting performance

- The structure serves multiple purposes including tool storage and garden organisation

Introduction and Project Overview

The addition of organised outdoor space significantly enhances property functionality for many UK residents. These structures provide practical solutions for common storage challenges.

Purpose of a Lean-To Shed

This type of outdoor building serves multiple practical functions. One builder created a structure beside his garage for firewood storage. Previously, the wood was piled behind an outbuilding exposed to weather.

The new construction kept the wood dry and closer to the main house. Another enthusiast attached one to a summerhouse. This separated gardening tools from the main workshop area.

Benefits of a DIY Approach

The DIY method offers substantial financial savings compared to prefabricated kits. Homeowners can allocate more budget toward quality materials. Complete customisation of dimensions and layout becomes possible.

The three-wall design makes construction inherently faster than traditional structures. This appeals to enthusiasts seeking achievable weekend projects. Proper construction improves wood-burning efficiency significantly.

| Feature | Lean-To Shed | Freestanding Shed |

|---|---|---|

| Construction Time | 2-3 days | 4-5 days |

| Material Cost | 25-40% less | Full material requirement |

| Space Efficiency | Uses existing wall | Requires full perimeter |

| Customisation | High flexibility | Limited by kit design |

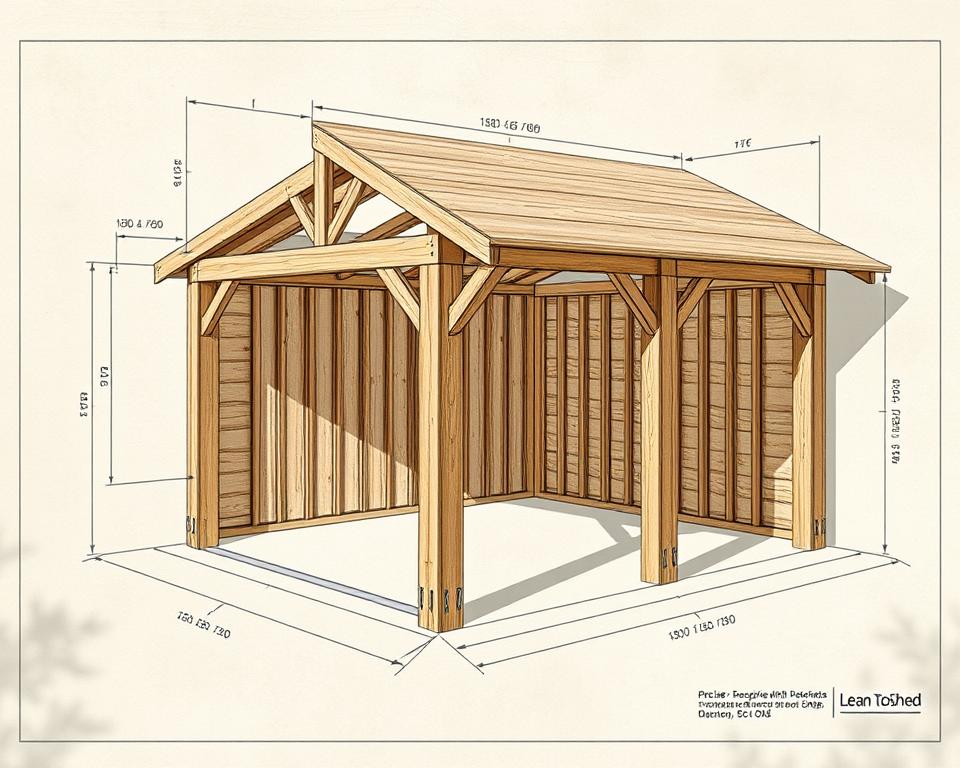

Planning Your Lean-To Shed

The initial planning phase determines the long-term success of your storage solution. Careful preparation ensures the structure meets practical needs while complying with local regulations.

Assessing Your Space and Location

Proper site evaluation begins with measuring available space along the existing wall. Ground conditions, drainage patterns, and accessibility requirements must be considered.

The ideal location should position the lean-to structure near where stored items will be used. This enhances convenience for accessing tools or firewood. Adequate headroom of approximately 7 feet ensures comfortable access.

Design Considerations for the UK Climate

UK weather conditions demand specific design adaptations. Adequate roof pitch ensures efficient water runoff and snow shedding. Wind direction and rain patterns influence structural orientation.

The size of your building shed should balance intended use with available space. Common dimensions range from 8 to 16 feet in length. Depth from the existing wall typically measures 6 to 8 feet.

| Planning Factor | Critical Consideration | UK-Specific Requirement |

|---|---|---|

| Roof Design | Minimum 10° pitch | Enhanced water drainage |

| Foundation | Stable ground assessment | Damp-proof membrane essential |

| Wall Attachment | Structural integrity check | Weather-resistant flashing |

| Door Placement | Optimal access planning | Sheltered from prevailing winds |

Local planning permissions must be verified before construction begins. Some areas require approval for structures attached to existing buildings. Boundary distances and fire safety regulations often apply.

Determining Shed Dimensions and Material Requirements

The structural integrity of an attached storage unit depends heavily on precise dimensional planning. Accurate measurements begin with assessing the available wall length on the existing structure. The desired depth extending outward and ceiling height must also accommodate stored items while fitting below existing eaves.

Standard shed dimensions include structures measuring 12 feet by 16 feet for substantial storage capacity. Smaller 8-foot by 12-foot versions suit compact spaces. The framework typically uses CLS timber measuring 38mm x 63mm, which can be ripped for cost-effectiveness.

Material requirements vary by project size but generally include 2×4 or 2×6 lumber for framing. Pressure-treated timber is essential for ground-contact elements to prevent rot in damp UK conditions. Calculating quantities involves determining wall studs spaced 16 to 24 inches apart.

Roofing material options include galvanised steel panels or roofing felt. Siding choices range from tongue-and-groove cladding to economical OSB sheeting. Proper planning ensures adequate supplies of fasteners, brackets, and protective finishes.

How to Build a Lean-To Shed?

The assembly process begins with gathering all necessary equipment and establishing safety protocols. Proper preparation ensures each construction phase proceeds efficiently and securely.

Essential Steps and Safety Measures

A methodical approach prevents costly errors during the construction process. The first step involves ground preparation and base construction. Wall framing follows, leading to roof assembly and final cladding.

Critical safety measures include wearing protective eyewear when operating cutting tools. Ear defenders prevent hearing damage from power equipment. All cuts should be made away from the body, and blades must stop completely before setting tools down.

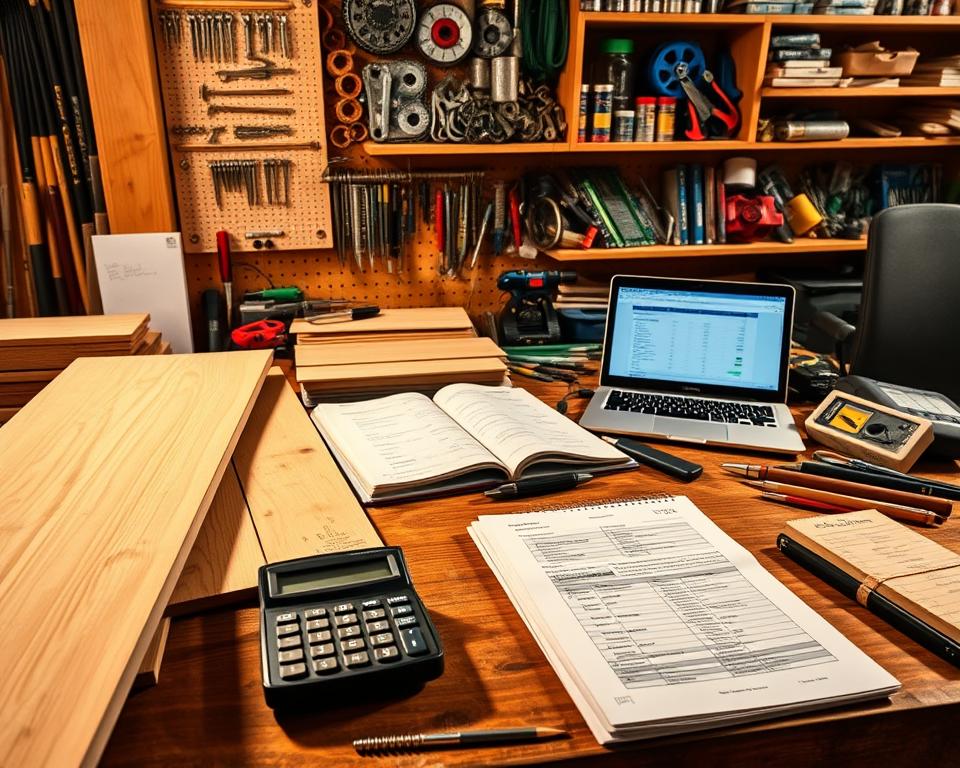

Tools and Materials Checklist

Essential hand tools include shovels, hammers, tape measures, and hand saws. Power equipment comprises drill drivers, impact drivers, and circular saws for efficient work. A sturdy workbench or sawhorses provides a stable cutting surface.

Material requirements encompass various lumber dimensions and specialised fasteners. Galvanised screws offer weather resistance, while clout nails secure roofing felt. Hardware like hinges and locking mechanisms complete the installation.

Organising supplies before starting streamlines the building process. This approach reduces time spent searching for items and maintains focus on safe working practices throughout the project.

Preparing the Foundation and Floor Structure

Proper ground preparation establishes the critical base upon which the entire construction relies for structural integrity. Builders must ensure the foundation remains stable under various weather conditions. This phase determines the longevity of the entire project.

Levelling the Ground and Setting Skid Beams

Ground preparation begins with removing topsoil and vegetation from the building area. Thorough tamping creates a firm, level surface that prevents future settling. This ensures stable foundations for the structure.

Skid beams constructed from 4×4 pressure-treated lumber run the full length. They provide a stable foundation that distributes weight evenly. This approach elevates the structure above ground moisture effectively.

For permanent installations, post holes approximately 3 feet deep can be dug. Obstacles like rocks may require alternative solutions such as concrete pads. One builder used two 80-pound bags of ready-mix concrete per footing.

Installing Floor Joists and Plywood

Floor joists cut from 2×6 treated lumber span the width at 14-inch to 16-inch intervals. This creates a robust framework supporting the flooring. The arrangement handles heavy items stored within.

Joists fasten to front and back beams using 3½-inch galvanised screws. Pilot holes prevent timber splitting during installation. This ensures secure connections throughout the floor structure.

Three-quarter-inch treated plywood sheets cover the framed floor. Attach to joists with 1⅝-inch screws spaced every 12 inches. This creates a solid, splinter-free surface resistant to moisture.

Constructing the Shed Walls

With the floor structure complete, the next phase involves creating the vertical supports. This step transforms the flat platform into a three-dimensional structure. Careful attention to detail during wall assembly ensures a square and sturdy frame.

The process begins by constructing each of the four walls separately on a flat, level surface. This method allows for precise work and accurate measurements. Using 2×4 lumber is standard for the framing.

Framing Techniques with 2×4 and 2×6 Lumber

Each wall frame features doubled-up 2×4 beams for the top and side plates. A single 2×4 serves as the bottom plate. This creates a robust perimeter for the structure.

Vertical studs, cut to 81 inches, are positioned at 22-inch intervals. They are secured to the frame using 2½-inch screws with pilot holes. This prevents the wood from splitting.

The front wall requires special consideration for the door opening. A 21-inch gap is left for a standard door. This opening is reinforced with doubled-up 2×6 boards on each side for added strength.

Once assembled, the side walls are raised and positioned on the floor frame. They are secured using 2½-inch galvanised screws driven through the bottom plates into the floor joists. These are spaced 8 inches apart.

Front and back walls are then raised and fixed between the side walls. Screws are driven both downward and laterally to lock all four walls together. A spirit level and carpenter’s square are used continuously to ensure walls are vertical and corners are square.

| Wall Component | Material Specification | Assembly Detail |

|---|---|---|

| Top & Side Plates | Doubled-up 2×4 lumber | Creates strong perimeter frame |

| Vertical Studs | 2×4 lumber, 81″ height | Spaced at 22-inch intervals |

| Door Reinforcement | Doubled-up 2×6 lumber | Provides solid hinge mounting |

| Wall-to-Floor Fixing | 2½” galvanised screws | Spaced 8 inches apart |

Adding Siding and External Finishing

The choice of cladding materials significantly impacts both the appearance and longevity of the construction. External siding transforms the basic framed structure into a weather-resistant shed. Material options include attractive tongue-and-groove cladding, economical OSB sheeting, or standard exterior-grade plywood.

Tongue-and-groove cladding installation begins at the bottom of each wall. The first board overhangs slightly to act as protective skirting. Working upward in manageable sections ensures proper alignment.

Strategic planning of cladding placement involves using shorter offcut pieces in less visible areas. Longer, continuous boards work best around doors and windows. This approach maintains visual appeal while minimising material waste.

| Material Type | Appearance | Durability | Cost | Installation |

|---|---|---|---|---|

| Tongue-and-Groove | Traditional, attractive | High with treatment | Moderate | More complex |

| OSB Sheeting | Functional | Medium | Economical | Straightforward |

| Exterior Plywood | Smooth finish | Good | Higher | Simple |

Corner junctions where wall panels meet require protective flashing trims. These are nailed on the exterior to direct water away from vulnerable joints. This simple addition significantly extends the structure’s lifespan.

Before final installation, all cladded panels benefit from at least two coats of wood preservative. Pay particular attention to end grain cuts that readily absorb moisture. The treated panels then screw securely to the base framework using corrosion-resistant fixings.

Building a Robust Shed Door

Crafting a durable entrance requires careful attention to structural details and security considerations. The door serves as both access point and protective barrier for the storage space.

Door Frame Construction and Reinforcement

Construction begins with precise measurement of the actual opening. Builders must account for trim thickness on both the door and frame, plus necessary clearances for hinges and locking mechanisms.

A robust frame utilises 2×4 or 2×6 lumber arranged in a Z-brace configuration. The diagonal brace angles downward toward the hinge side to counteract the door’s weight. This prevents sagging over time.

Installing Hinges and Security Features

Heavy-duty 300mm hinges should be positioned at the top and bottom of the door. For solo installation, prop the door on a plank resting on bricks. This allows foot control while securing hinges.

Security enhancements include replacing standard screws with coach bolts. These require tools for removal, preventing external tampering. A stop lat prevents the door from pushing inward excessively.

Creating the Lean-To Roof Framework

Roof construction marks the transition from basic framing to complete weather protection for the storage area. This phase requires careful attention to structural connections and proper pitch calculation.

Cutting and Installing Rafters

The roof framework begins with horizontal stringers bolted securely to the existing wall. Builders use substantial lag screws that penetrate deeply into structural members. This creates a solid foundation for the entire roof system.

Rafters cut from 2×4 beams require precise notches at both ends. These notches allow secure seating on wall-mounted stringers and freestanding posts. For a typical structure, nine rafters spaced 24 inches apart provide adequate support.

The roof pitch must ensure efficient water runoff while fitting below existing eaves. Proper calculation prevents water pooling and structural issues.

Using Collar Ties and Support Beams

Collar ties installed between the lower stringer and each rafter prevent sagging. Positioned approximately 2 feet from the wall, these supports maintain structural integrity.

Strategic material use yields two supports from each standard 8-foot board. Metal connectors like L-brackets and hurricane ties offer superior holding power. This approach withstands heavy snow loads and high winds effectively.

The completed framework creates a durable roof structure ready for panel installation. Proper execution ensures long-term performance in varied weather conditions.

Attaching Roofing Panels and Waterproofing

The final stage of enclosing the structure focuses on creating a weatherproof roof system. This critical phase ensures long-term protection for the stored contents from the UK’s variable climate.

Before the main panels are fixed, horizontal nailers made from 2×4 lumber are attached across the rafters. They are spaced approximately two feet apart. This creates a sturdy grid for securing the roofing materials.

Areas expecting extra stress, like zones where snow might slide from a neighbouring building, benefit from additional reinforcement. Using scrap 2×4 pieces here helps distribute impact loads effectively.

Installing Roofing Panels with Galvanised Screws

For corrugated metal roof panels, galvanised steel sheets are overlapped as specified. They are secured using specialised #10 1½-inch hex-head screws with rubber washers. These washers create essential watertight seals around each fastener.

An alternative approach involves using three-quarter-inch plywood sheets to create a solid deck. The sheets are screwed to the rafters with 1⅝-inch screws spaced every eight inches. This prevents lifting in high winds.

Roofing felt is then applied from the bottom upwards. Each course overlaps the one below to shed water. It is secured with clout nails along the overhang, with corners folded and sealed using bitumen adhesive.

Finishing touches include nailing treated timber trim around the three exposed roof edges. The top edge adjacent to the existing building receives aluminium flashing instead. This ensures a completely water-tight integration.

Structural Stability and Custom Additions

The resilience of an outdoor structure depends on anticipating potential stress points and reinforcing accordingly. One builder experienced this when anticipating heavy snow sliding from his garage roof onto the new construction.

After completion, the storage unit successfully withstood a storm depositing 14 inches of wet snow. This confirmed the structural integrity achieved through thoughtful planning.

Strategic reinforcement using additional 2×4 material in high-impact zones proved effective. This approach prevented oversizing the entire framework while providing necessary support.

Proper post placement significantly affects stability. Using 4×4 treated posts set in concrete footings prevents wall spreading under roof loads.

The connection between the lean-to roof and existing building wall requires robust attachment. Lag screws penetrating deep into the building’s frame ensure lasting stability.

Custom additions like internal shelving should anchor directly to wall studs or rafters. This ensures they safely support intended loads without compromising the main structure.

Regular inspections after severe weather help identify developing issues early. This proactive approach maintains long-term performance and safety.

Customising the Shed for Specific Uses

Customisation transforms a basic outdoor building into a highly functional space that precisely meets individual requirements. The interior layout determines how effectively the structure serves its intended purpose.

One builder discovered excellent results by mounting storage hooks directly onto wall studs. This approach kept gardening tools like spades organised and accessible. For remaining walls, adjustable plastic shelves offered flexibility to modify arrangements as needs changed.

Storage Solutions and Organisational Tips

The builder reported significant benefits from keeping wood dry inside the structure. Properly seasoned firewood generated considerably more heat than damp wood stored outdoors. This demonstrated the practical value of tailored storage solutions.

Different applications require specific configurations. Bicycle storage might use wall-mounted hooks, while potting sheds benefit from work surfaces and specialised shelving. Sports equipment storage needs careful planning for item sizes and access frequency.

Successful organisation involves creating distinct zones for different item categories. This prevents clutter and ensures each shed serves its purpose efficiently. The right internal layout maximises both accessibility and storage capacity.

Budgeting, Material Sourcing and Cost Considerations

Navigating material costs and sourcing challenges requires strategic budgeting approaches. Recent timber price increases and supply issues make careful planning essential for any outdoor storage project.

Builders should compare prices across multiple suppliers. Special ordering significant items like roofing panels can yield substantial savings. One builder saved approximately $3 per panel by ordering steel roofing through Menards while purchasing other materials locally.

Pressure-treated lumber offers superior longevity for ground-contact applications despite commanding premium pricing. Untreated timber presents lower initial cost but requires investment in quality preservatives. Multiple treatment coats are essential, particularly for end grain cuts that absorb moisture readily.

Cost-effective strategies include purchasing full-sized CLS timber and ripping it in half using a table saw. This approach essentially doubles the linear footage obtained from each purchase. Those unable to rip timber could use 40mm studwork instead.

Realistic cost estimation for a modest structure typically ranges from several hundred to over a thousand pounds. This represents significant savings compared to prefabricated kits. Hidden expenses often include concrete, additional fasteners, wood preservatives, and potential permit fees.

Strategic purchasing involves buying sufficient quantities without over-purchasing. Careful measurement and cutting lists minimise waste and maximise budget efficiency. Proper planning ensures the shed project remains financially manageable while delivering quality results.

Essential Safety Tips and Recommended Tools

A comprehensive approach to personal protection and tool handling ensures that building projects proceed without incident or injury. Proper safety protocols protect both the builder and the integrity of the construction work.

Before commencing any work, organisers should allocate sufficient time to review all necessary precautions. This preparation prevents rushed decisions that could compromise workplace security.

Personal Protective Equipment (PPE)

Essential protective equipment forms the foundation of secure construction practices. Safety goggles shield eyes from flying debris during cutting operations. Ear defenders protect hearing from loud power tools like circular saws.

Sturdy work gloves prevent splinters and cuts when handling rough timber. Durable footwear provides stability when moving materials around the work area. Each item serves a specific protective function.

Safe Use of Power and Hand Tools

Circular saw operation demands particular attention to blade direction and work piece stability. Operators should always cut away from their body position. The blade must stop completely before setting the saw down.

Drill drivers require careful bit selection and appropriate speed settings for different materials. Bits can bind unexpectedly in dense timber, potentially wrenching the tool. A firm grip prevents accidental tool movement.

Hand tools like hammers and chisels demand respect for their sharp edges and striking surfaces. Proper technique prevents slips that could cause serious injuries. Stable work surfaces ensure secure operation of all equipment.

Regular maintenance of tools contributes significantly to safe operation. Sharp blades require less force and produce cleaner cuts than dull alternatives. Electrical cords should be inspected regularly for damage.

Conclusion

Undertaking a DIY storage project offers homeowners both practical benefits and personal satisfaction. The lean-to design provides an accessible entry point for those new to construction work. This approach allows for significant cost savings compared to purchasing pre-made options.

Following the step-by-step process outlined ensures successful completion of the project. Careful planning and precise measurements form the foundation of any successful building endeavour. Quality materials and proper safety practices guarantee long-lasting results.

The versatility of the lean-to shed accommodates various storage needs from garden tools to firewood. With proper care, the finished structure will serve reliably for many years. The time invested in learning to build pays dividends in both utility and skill development.

Ultimately, a well-executed lean-to shed becomes a valuable property enhancement. The sense of accomplishment from seeing the project through to completeion is immensely rewarding for any DIY enthusiast.

FAQ

What is the minimum recommended roof pitch for a lean-to shed in the UK?

A minimum pitch of 10 to 15 degrees is generally recommended to ensure adequate rainwater runoff. A steeper pitch may be necessary in areas with heavy snowfall to prevent accumulation on the shed roof.

Is pressure-treated timber essential for the entire shed structure?

Pressure-treated wood is crucial for any components in direct contact with the ground, such as skid beams and the bottom plate of the walls. For the upper sections of the frame and roof, standard timber is often sufficient, especially when protected by proper siding and roofing materials.

How much space should I leave between the shed and my house wall?

It is advisable to maintain a small gap of about 25 to 50 millimetres between the shed roof and the house wall. This space allows for air circulation and prevents moisture from being trapped against the house’s siding, which could lead to damp issues.

Can I attach the shed’s rafters directly to my house?

Attaching the shed roof framework directly to a house wall requires careful consideration. It is often necessary to fix a sturdy ledger board securely to the house’s wall studs. For structural integrity and to avoid damaging the house, consulting a builder or structural engineer is highly recommended before proceeding.

What is the most suitable foundation for a lean-to shed?

A simple and effective foundation for a small to medium-sized lean-to shed involves using pressure-treated timber skids placed on a level gravel pad. For larger sheds or softer ground, concrete paving slabs or a concrete footing may provide a more stable and long-lasting base.

What type of roofing panels are best for this project?

Corrugated bitumen sheets or PVC panels are popular choices for DIY lean-to sheds. They are lightweight, easy to cut and install with galvanised screws, and provide excellent waterproofing. Metal roofing panels are another durable, though sometimes more costly, option.

How can I ensure my shed door is square and operates smoothly?

Construct the door frame on a flat surface and use diagonal measurements to check for squareness before fixing it permanently. Reinforcing the corners with metal braces and using three sturdy hinges per door will help prevent sagging over time, ensuring smooth operation.