What Is Pressure Treatment and How Does It Protect Wood?

Timber used for outdoor projects faces constant challenges. Once cut from living trees, wood becomes vulnerable to the elements. Moisture, in particular, can lead to rot and decay, compromising a structure’s integrity.

This is where a specialised preservation process comes into play. It involves forcing protective chemicals deep into the timber’s cellular structure. This action creates a robust barrier against biological threats.

The method significantly extends the service life of wood. Untreated timber might last only 5-8 years in a garden setting. After this treatment, the same wood can endure for 20-25 years, even in damp conditions.

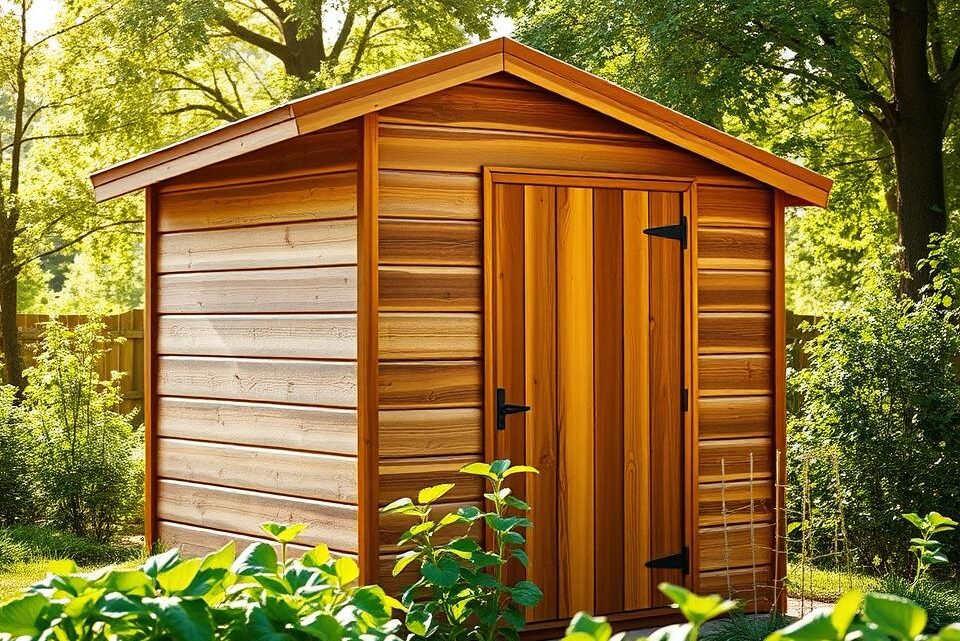

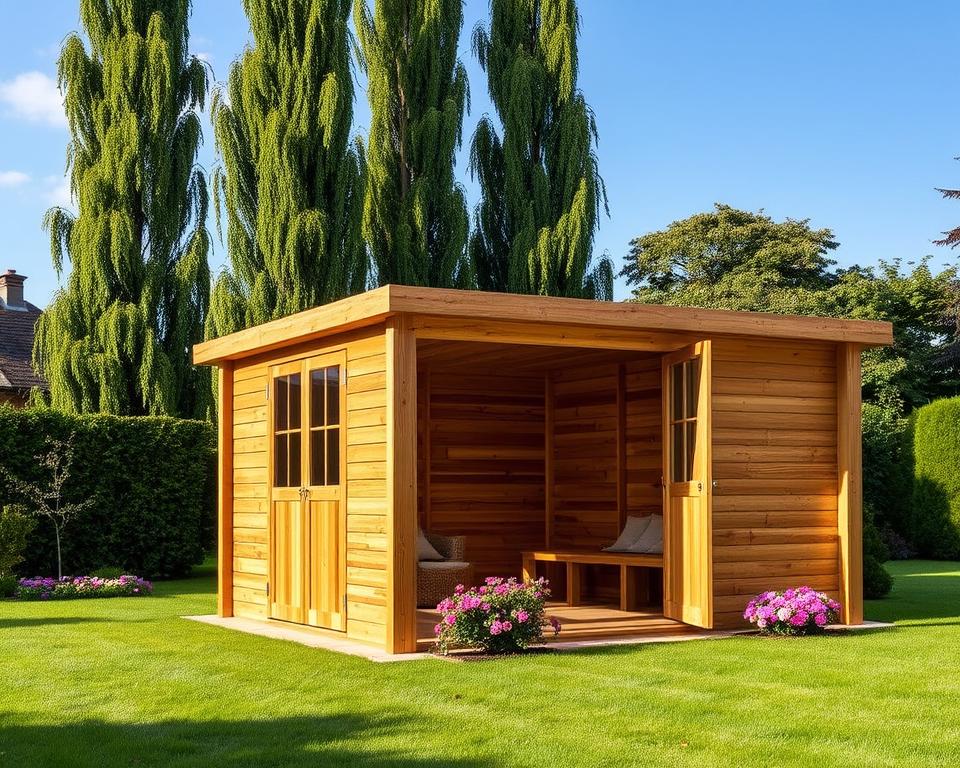

Commonly used for sheds, summerhouses, and workshops, this treated wood offers long-lasting performance. Initially, it displays a green hue due to copper-based preservatives. This colour naturally fades over time to a sandy-brown shade.

Inhaltsverzeichnis

Key Takeaways

- Pressure treatment is a wood preservation technique that significantly increases timber’s durability.

- The process forces protective chemicals deep into the wood’s cellular structure.

- It defends against rot, decay, and insect infestation caused by moisture.

- Treated timber is ideal for garden buildings like sheds and summerhouses.

- The initial green colour of the wood fades naturally over time.

- This method can extend wood’s lifespan from 5-8 years to over two decades.

Understanding the Pressure Treatment Process

Transforming vulnerable wood into resilient building material requires sophisticated industrial methods. This multi-stage operation ensures deep penetration of protective chemicals. The entire procedure demands precision and specialised equipment.

Preparation: Debarking, Incising, and Drying

Raw timber undergoes thorough preparation before the main procedure. Debarking removes outer layers using specialised machinery. Incising creates small openings with steel teeth for better chemical absorption.

Proper drying is essential for optimal results. Moisture content must be carefully controlled to allow preservative penetration.

Vacuum Extraction and Pressurisation Steps

The core process begins with vacuum extraction. Air is removed from timber cells to create space for treatment solutions. This vacuum phase prepares the material for chemical infusion.

High pressure forces preservatives deep into the wood’s cellular structure. Operating at 140-150 psi, this step ensures comprehensive protection.

Chemical Penetration and Retention Techniques

Two primary methods govern chemical distribution within the timber. The full-cell approach saturates both cell walls and lumens. Alternatively, empty-cell techniques focus on wall penetration only.

Retention levels measure preservative amounts remaining after treatment. This quality control ensures long-term effectiveness against decay.

What Is Pressure Treatment and How Does It Protect Wood?

Modern wood preservation relies on sophisticated chemical solutions that penetrate deep into timber’s cellular structure. These formulations create lasting protection against environmental threats.

The Role of Copper and Preservative Chemicals

Since the mid-2000s, copper has revolutionised wood preservation methods. This versatile metal doesn’t merely prevent fungal growth—it actively oxidises enzymes and proteins within destructive organisms. The result is a hostile environment that deters mould, mildew, and wood-boring insects.

Preservative chemicals fall into three main categories. Tar oil-based options like creosote suit heavy-duty applications like railway sleepers. Oil-borne preservatives work well for commercial interiors. Water-borne formulations, often copper-based, dominate residential use.

The industry term “tanalising” refers to treatments using solutions like Tanalith E. This specialised chemical mixture ensures deep penetration and lasting protection. Modern formulations have evolved significantly since older treatments.

Comparing Pressure Treatment to Conventional Methods

Surface-applied wood preservers offer limited protection compared to industrial processes. Brush-on products require annual reapplication and provide superficial coverage. They cannot match the deep penetration achieved through specialised equipment.

The industrial precision of professional treatment facilities cannot be replicated at home. Controlled conditions and high-pressure systems ensure chemicals reach the wood’s core. This comprehensive approach delivers superior longevity against moisture, decay, and insect damage.

Different preservative formulations suit specific applications. Residential garden structures benefit from copper-based solutions, while commercial products may use alternative chemicals. Each formulation provides targeted protection based on intended use.

Key Benefits and Maintenance of Treated Timber

Choosing the right materials for garden construction ensures lasting performance and reduced upkeep. Specially processed timber offers significant advantages for outdoor projects.

Long-Lasting Defence Against Rot and Insect Damage

This preservation method extends anti-rot guarantees from ten to fifteen years. The process creates a hostile environment for fungi and wood-boring insects. Manufacturers like BillyOh now include this as standard in products such as their Switch Tongue and Groove Pent Shed.

Customers can verify options in the “Select Treatment” section on product pages. The initial green hue indicates active protection against weather damage.

Enhancing Timber Appearance and Structural Integrity

Once thoroughly dried, this material accepts stains and paints beautifully. Proper drying ensures finishes adhere correctly for durable results. Combining shed stain with wood preserver provides both aesthetic and structural benefits.

Practical Applications in Garden Buildings and Other Structures

This timber excels in various outdoor applications. From fencing to decking foundations, it offers reliable performance. For those choosing untreated options, annual maintenance becomes necessary.

| Maintenance Aspect | Treated Timber | Untreated Timber |

|---|---|---|

| Anti-rot Guarantee | 10-15 years | None |

| Annual Maintenance | Minimal | Required |

| Paint/Stain Application | After drying | Immediate |

| Weather Resistance | High | Low |

The moisture content affects finishing options. Oil-based products require completely dry surfaces. Water-based alternatives also need proper drying for optimal absorption.

Conclusion

The decision to select appropriate timber for garden projects significantly impacts long-term performance and maintenance requirements. This specialised preservation process represents more than just an optional feature—it’s a fundamental investment in durability.

Choosing pressure-treated products demonstrates a commitment to quality that pays dividends for many years. The enhanced protection against environmental elements ensures reliable performance under challenging conditions.

When evaluating timber for outdoor structures, consumers should verify treatment specifications on product pages. Additional technical information is often available through supplier guides.

The result is measurable protection that extends service life substantially. This approach delivers superior value by reducing maintenance burdens while maintaining structural integrity.

FAQ

What is the purpose of the pressure treatment process for timber?

The process forces preservative chemicals deep into the wood’s cellular structure. This creates a durable barrier that protects the timber from moisture, fungal decay, and insect attack, significantly extending its service life.

How does pressure treated wood compare to products treated with conventional methods?

Pressure treatment offers far superior protection. Unlike surface-applied coatings, it ensures deep, even penetration of preservatives. This results in long-lasting defence that won’t wash or wear away, making it ideal for sheds and other outdoor structures.

What maintenance is required for pressure treated garden buildings?

Properly treated timber requires minimal upkeep. While an occasional clean can maintain its appearance, the preservatives within the wood provide continuous protection against the elements for many years without the need for regular re-treatment.

Does pressure treatment alter the colour of the wood?

Initially, yes. The process often gives the timber a green or brown hue due to the copper-based preservatives used. This colour will gradually weather to a natural silver-grey over time if left untreated with additional stains or paints.

How long does the protection from pressure treatment last?

The longevity depends on the product’s use and exposure. For above-ground applications like garden buildings, it can last for decades. When used in ground contact, the protection remains effective for many years, safeguarding the structure’s integrity.