Understanding How Pressure Treated Wood Responds to Water

Modified timber has become essential for outdoor construction projects throughout the United Kingdom. This material offers enhanced protection against decay, fungi, and insects compared to untreated alternatives. Builders and homeowners value its durability in challenging environments.

The relationship between this specialised timber and moisture involves complex factors. The treatment process, preservative chemicals, and environmental exposure all play crucial roles. Understanding these interactions helps with material selection and maintenance planning.

This guide examines the scientific principles behind wood modification. It clarifies the difference between waterproofing and water resistance. Practical advice supports successful project outcomes and extends the life of outdoor structures.

Inhaltsverzeichnis

Key Takeaways

- Modified timber provides superior protection against decay and insects

- The treatment process enhances material durability in outdoor settings

- Understanding moisture interaction is vital for proper material selection

- Different preservative chemicals offer varying levels of protection

- Regular maintenance extends the lifespan of treated timber structures

- Environmental conditions significantly impact material performance

- Proper installation techniques maximise the benefits of treatment

Introduction to Pressure Treated Wood and Its Exposure to Moisture

Timber modification represents one of humanity’s oldest construction innovations, dating back to ancient civilisations seeking to protect their structures. Early methods involved plant-based oils to slow fungal decay, while contemporary approaches use advanced chemical preservatives.

This evolution addresses timber’s natural vulnerability to moisture, weathering, and biological attack. Understanding these treatment methods helps builders select appropriate materials for specific environmental conditions.

Overview of Wood Treatment Methods

Modern preservation techniques have significantly advanced from historical practices. The industry now offers several treatment options including pressure treatment, thermal modification, and surface coatings.

Pressure treatment, often called tanalised timber, forces preservatives deep into wood cells. This process creates a protective barrier against decay organisms and insects. Different methods suit various applications and exposure levels.

Key Benefits and Limitations

Pressure treated lumber offers substantial durability improvements over untreated alternatives. Service life extends from 5-8 years to 20-25 years in moist conditions. Enhanced resistance to termites and improved dimensional stability are significant advantages.

However, limitations include initial moisture content requiring drying periods before finishing. Potential chemical leaching and higher initial costs should be considered. The characteristic green tint from copper-based preservatives may affect aesthetic choices.

Understanding these factors enables appropriate material selection for projects. This knowledge ensures optimal performance while managing maintenance expectations in wet environments.

How Pressure Treated Wood Responds to Water

Specially treated building materials offer enhanced protection against water-related damage. This material demonstrates significantly better performance than untreated wood when dealing with moisture exposure.

The treatment process creates a protective barrier within the cellular structure. This barrier helps repel water and prevents rapid moisture absorption. However, it’s crucial to understand that water-resistant differs from waterproof.

Intermittent exposure presents little challenge for this material. Rain showers, morning dew, and routine cleaning cause minimal issues. The surface can dry effectively between wetting events.

Continuous water exposure tells a different story. Prolonged contact with standing water can overwhelm the protective treatment. The result may include fungal growth and structural weakening.

Common preservatives like Alkaline Copper Quaternary (ACQ) enhance initial resistance. Their water-based nature helps create chemical barriers within the wood. Yet even advanced treatments have practical limits.

Challenging scenarios include poor drainage areas and constant high humidity. Builders need know that proper installation complements the material’s properties. Adequate ventilation and elevation help maintain performance.

This material withstands normal UK weather conditions exceptionally well. Understanding its limitations ensures successful long-term performance in outdoor applications.

Understanding the Pressure Treatment Process

The transformation of ordinary timber into weather-resistant construction material involves a carefully engineered pressure treatment procedure. This industrial process fundamentally enhances lumber durability through deep chemical penetration.

Manufacturers begin by preparing lumber through precise cutting and kiln drying. Proper moisture reduction ensures optimal chemical absorption during the treatment process.

Vacuum and Chemical Penetration Explained

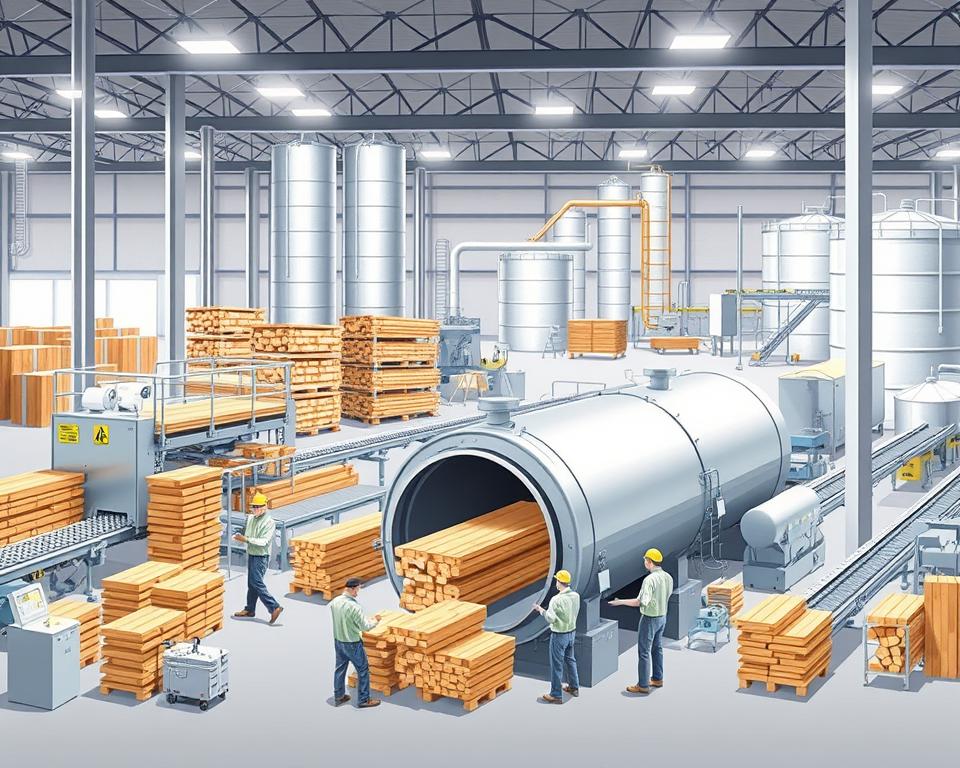

The core of pressure treatment involves specialised cylindrical vessels. Workers load prepared timber into these massive cylinders, typically reaching 150 feet in length.

An initial vacuum stage removes air from the wood’s cellular structure. This creates negative pressure that draws preservative chemicals deep into the timber. The vacuum process ensures complete penetration throughout each board.

Following vacuum extraction, the cylinder floods with chemical solutions. High pressure applications force preservatives into the evacuated cellular spaces. This creates a protective barrier within the lumber’s structure.

Full-Cell Versus Empty-Cell Techniques

Two primary methodologies dominate modern treatment processes. The full-cell method, invented by John Bethell in 1838, completely saturates wood cells with preservatives.

This approach uses initial vacuum extraction followed by high-pressure chemical infusion. It achieves maximum chemical retention for severe exposure applications.

The empty-cell technique employs compressed air within cell lumens. This method coats cell walls while allowing excess chemicals to drain. It provides effective protection with reduced chemical volumes.

Both methods utilise pressure cycles between 140-150 psi. The choice depends on intended application and required protection levels.

Factors Influencing the Durability of Treated Wood in Wet Conditions

Several key variables govern the extended service life of chemically enhanced building materials exposed to wet conditions. The interplay between treatment quality and environmental factors determines long-term performance outcomes.

Role of Preservative Chemicals and Copper Additives

Preservative formulations form the foundation of material protection. Three main categories dominate the industry: tar oil based, oil-borne, and water-borne solutions. Copper plays a vital role in modern water-based systems.

The characteristic green tint visible in protected lumber results from copper compounds. This colour provides visual confirmation of proper chemical distribution. Copper acts as the primary fungicidal agent against decay organisms.

Impact of Exposure and Environmental Conditions

Environmental factors significantly affect material performance. Frequency of wetting, temperature changes, and soil contact all influence durability. Constant moisture can lead to chemical leaching over time.

Retention level measures the amount of preservative remaining after treatment. Higher values provide greater protection for severe exposure applications. Industry standards specify minimum requirements based on anticipated conditions.

| Preservative Type | Common Examples | Primary Applications | Key Characteristics |

|---|---|---|---|

| Tar Oil Based | Creosote | Industrial uses, railway sleepers | Dark appearance, strong odour |

| Oil-Borne | Pentachlorophenol | Utility poles, marine structures | Water repellent properties |

| Water-Borne | Copper-based compounds | Residential decks, fencing | Green tint, fungal resistance |

Maintenance and Protective Coatings for Treated Wood

Applying a protective finish significantly boosts the longevity of pressure treated materials. These coatings add an extra shield against the elements. They work alongside the internal preservatives.

Water-based paints are an excellent choice for this task. They adhere well and create a durable barrier. This layer helps keep moisture from penetrating the lumber.

Quality exterior paint offers multiple benefits. It protects against UV rays, rain, and snow. It also covers the characteristic green tint of the material.

Painting Techniques and Drying Times

Patience is crucial when preparing treated lumber for painting. The material must dry thoroughly after the treatment process. This drying period allows excess moisture to evaporate.

Typically, this takes three to four months in warmer weather. During a British winter, it can extend to six months. Rushing this step can lead to peeling and poor adhesion.

Wax and oil treatments are less affected by initial moisture levels. They can be applied sooner than water-based finishes.

Test Methods for Moisture Content and Surface Cure

A simple test determines if the surface is ready for coating. Sprinkle a few drops of water onto the lumber. If the water soaks in, the material is ready.

If the water beads on the surface, it needs more time to dry. This simple check prevents application errors. It ensures the coating bonds correctly for long-lasting protection.

Regular maintenance of the coating is essential. Inspect it annually for wear and recoat as needed. This upkeep preserves the material’s appearance and structural integrity.

Comparing Pressure Treated Wood with Alternative Treatment Methods

Understanding the fundamental differences between treatment approaches helps specifiers make informed material choices. The timber industry offers multiple modification methods designed to enhance durability in outdoor settings.

Two primary technologies dominate modern timber enhancement: chemical preservation and thermal modification. Each employs distinct mechanisms to achieve decay resistance.

Differences Between Pressure Treatment and Thermal Modification

Chemical preservation forces fungicidal compounds deep into cellular structure. This creates a protective barrier against decay organisms. The process uses specialised equipment to achieve thorough penetration.

Thermal modification employs controlled high-temperature exposure instead. Temperatures between 160-260°C alter the wood’s chemical composition. This method degrades hemi-cellulose, removing food sources for fungi.

The thermal process also reduces equilibrium moisture content. This results in material that absorbs less water and resists dimensional changes. However, it can reduce load-bearing strength by up to 30%.

| Treatment Method | Protection Mechanism | Best Applications | Key Considerations |

|---|---|---|---|

| Chemical Preservation | Fungicidal compounds | High-moisture, ground contact | Maximum decay resistance |

| Thermal Modification | Heat-altered structure | Above-ground, moderate exposure | Superior dimensional stability |

Environmental factors influence selection between these wood treatment types. Thermal modification gains popularity for chemical-free processes. Chemical methods remain dominant where maximum protection is essential.

Proper understanding enables balanced selection based on project requirements. Factors include moisture exposure, structural demands, and environmental priorities.

Practical Applications and Environmental Considerations in the UK

In the UK, selecting the right timber for outdoor projects involves balancing durability needs with ecological responsibility. Builders must understand where enhanced materials provide genuine value versus where alternatives might suffice.

Optimising Use in Outdoor Projects and Decking

Decking represents one of the most common applications for specially treated lumber. The material’s resistance to decay makes it ideal for support structures that encounter ground moisture.

Proper installation techniques significantly enhance performance. Elevating boards above ground level reduces direct contact with damp surfaces. Adequate spacing between planks promotes air circulation and drying.

For severe exposure conditions like fence posts, full-cell treatment provides maximum protection. This method ensures higher preservative retention where timber meets soil.

Sustainable Practices and Health Considerations

Environmental awareness has transformed treatment methods over recent years. The phase-out of CCA for residential use reflects growing health concerns.

Disposal requires careful handling at the end of a structure’s life. Controlled landfill strategies prevent chemical leaching into ecosystems. Burning treated wood releases toxic compounds and should be avoided.

The extended service life—from 5-8 to 20-25 years—offers sustainability benefits through reduced replacement frequency. This advantage must be weighed against the material’s complete environmental impact.

Conclusion

Maximising the service life of protected timber structures demands attention to both initial construction details and ongoing care. This specially processed material dramatically extends performance compared to untreated wood, transforming short-lived lumber into decades-lasting solutions.

The fundamental principle involves deep chemical penetration creating resistance rather than complete waterproofing. Proper installation techniques like elevation and drainage complement the preservative treatment. Regular maintenance inspections preserve structural integrity throughout the material’s lifespan.

Builders and homeowners need to understand that optimal results require appropriate material selection for specific conditions. With informed decisions and consistent upkeep, these enhanced building products deliver their full durability benefits for outdoor projects across the United Kingdom.

FAQ

What is the main purpose of the pressure treatment process for timber?

The primary goal is to force preservative chemicals deep into the wood’s cellular structure. This process significantly enhances the material’s resistance to decay, insect attack, and fungal growth, especially when used in ground contact or other damp environments.

How does pressure treated lumber react when it gets wet?

While the treatment offers robust protection, the timber can still absorb moisture. This may cause slight swelling and potential warping if the wood was not fully dried before installation. However, the embedded chemicals prevent the moisture from leading to rot, which would rapidly degrade untreated wood.

Is special maintenance required for a deck made from treated wood?

Yes, periodic maintenance is recommended to prolong its life. Applying a protective coating or decking oil after the timber has thoroughly dried and cured can help manage moisture uptake, reduce surface cracking, and maintain its appearance. The drying time can vary from weeks to months depending on the weather.

What are the key differences between full-cell and empty-cell treatment methods?

The full-cell process aims to retain the maximum amount of preservative within the timber’s cells, offering a very high level of protection. The empty-cell technique forces chemicals into the wood but then recovers some excess, resulting in a lower chemical retention that is often sufficient for many above-ground applications.

Can you paint or stain pressure treated wood immediately after purchase?

It is not advisable. The timber needs time to dry out and for the surface to cure completely. Painting or staining too soon can trap moisture within the wood, leading to poor adhesion and premature coating failure. A simple moisture meter test can determine if the wood is ready.

How does pressure treated timber compare to thermally modified wood in wet conditions?

Both methods improve durability. Pressure treatment uses chemical preservatives like copper to protect the wood from biological threats. Thermal modification uses heat to alter the wood’s structure, making it less absorbent and more dimensionally stable, but it may not offer the same level of insect resistance for ground contact use.