How to Dismantle a Shed

Taking apart a garden shed can seem like a huge job. Many people imagine it requires special skills or a lot of strength. But this task is often more manageable than it first appears. With a clear plan and the right approach, anyone can successfully complete this project.

Think of the structure as a large construction set. The key is a systematic method, not force. People decide to take down their garden building for various reasons. Perhaps they are replacing it with a new one, moving it to a different spot, or creating space for other garden uses.

Proper planning and patience are absolutely essential. This careful preparation ensures the work is done safely and efficiently. It also helps to avoid damage to the materials, making reuse or recycling a real possibility.

This comprehensive guide will walk through the entire process. It covers essential preparation, important safety measures, the tools you will need, and clear step-by-step instructions. Whether the building is made of wood, metal, or composite materials, the core principles remain the same.

Inhaltsverzeichnis

Key Takeaways

- A systematic approach makes the task manageable.

- Proper planning is crucial for safety and efficiency.

- The process is similar for wooden, metal, and composite structures.

- Common reasons include replacement, relocation, or garden clearance.

- Careful work allows materials to be reused or recycled.

Introduction: Redefining Your Garden Space

Over time, garden buildings can transform from useful assets into problematic fixtures requiring attention. What once served as practical storage may now hinder the garden’s potential. This evolution often prompts homeowners to reconsider their outdoor space entirely.

Understanding the Need for Dismantling

After many years of exposure to British weather, garden sheds frequently develop structural issues. Rotting timber, warped panels, and draughty construction become common problems. These conditions make the building unsafe or impractical for continued use.

Space considerations also play a crucial role in the decision-making process. A shed that seemed appropriately sized decades ago may now occupy valuable garden real estate. This space could be better utilised for entertaining areas, landscaping, or more functional modern structures.

Aesthetic concerns represent another significant factor. Garden design trends evolve, and older sheds can become eyesores that detract from outdoor enjoyment. Their outdated style may no longer complement the contemporary garden landscape.

Benefits of a Clear Outdoor Area

Removing an ageing garden building opens up tremendous possibilities. Homeowners reclaim forgotten vistas and create opportunities for complete garden redesign. The cleared space becomes a blank canvas for life-enhancing changes.

Modern garden buildings offer far more than basic storage functionality. They can serve as home offices, exercise spaces, or year-round relaxation areas. This transformation adds genuine value to daily life and property appeal.

| Traditional Shed Purpose | Modern Garden Building Use | Space Utilisation Impact |

|---|---|---|

| Basic tool storage | Home office workspace | Low value per square metre |

| Seasonal equipment | Year-round gym facility | Limited functionality |

| Infrequent access | Daily relaxation space | Underutilised area |

The positional advantages of clearing space cannot be overstated. Many older sheds block desirable views or create awkward garden flow. Their removal allows for better sunlight exposure and improved outdoor circulation.

Planning and Preparing the Dismantling Process

The foundation for a smooth disassembly operation lies in meticulous pre-project organisation. Thorough preparation is the single most effective way to prevent accidents, avoid material damage, and eliminate unnecessary delays during the main process.

Assessing the Shed’s Structure

The first practical step is to completely empty the garden shed. Remove all stored items, shelving, and loose fittings. This provides a clear view of the structure’s components and creates safe working space.

Next, conduct a detailed structural assessment. Examine how the building was constructed. Identify connection points and determine whether components are screwed or nailed together. Note any areas of deterioration that will require extra care during the diy project.

If the original assembly instructions are available, they can provide invaluable insights. They often reveal which parts are heavier or more complex, allowing for better planning.

Creating a Detailed Work Plan

Before starting, decide the ultimate fate of the shed materials. This decision fundamentally affects the approach. Will components be reused, sold, or disposed of? Each path requires a different level of care.

For reusable structures, keep all fixings and hardware in a safe place. This ensures everything is ready for the new owner. For disposal, clear a space to stack materials neatly by type—wood, metal, glass—to streamline recycling.

Arrange for help if needed and schedule work during favourable weather. Notify neighbours if the project may cause disruption. Designate areas for material sorting and confirm local recycling centre regulations in advance.

| Preparation Step | Key Action | Primary Benefit |

|---|---|---|

| Clearing the Shed | Remove all contents and internal fittings | Creates safe, unobstructed workspace |

| Structural Assessment | Identify fixings and weak points | Informs a safe, logical disassembly sequence |

| Material Fate Decision | Choose reuse, sale, or disposal path | Determines the level of care required |

| Logistical Planning | Arrange help, space, and waste management | Saves time and prevents mid-project issues |

Safety Precautions for Dismantling a Shed

Without proper safety measures, what should be a straightforward project can quickly become hazardous. Rushing the process or taking shortcuts significantly increases the risk of serious injuries from heavy falling components and structural collapse.

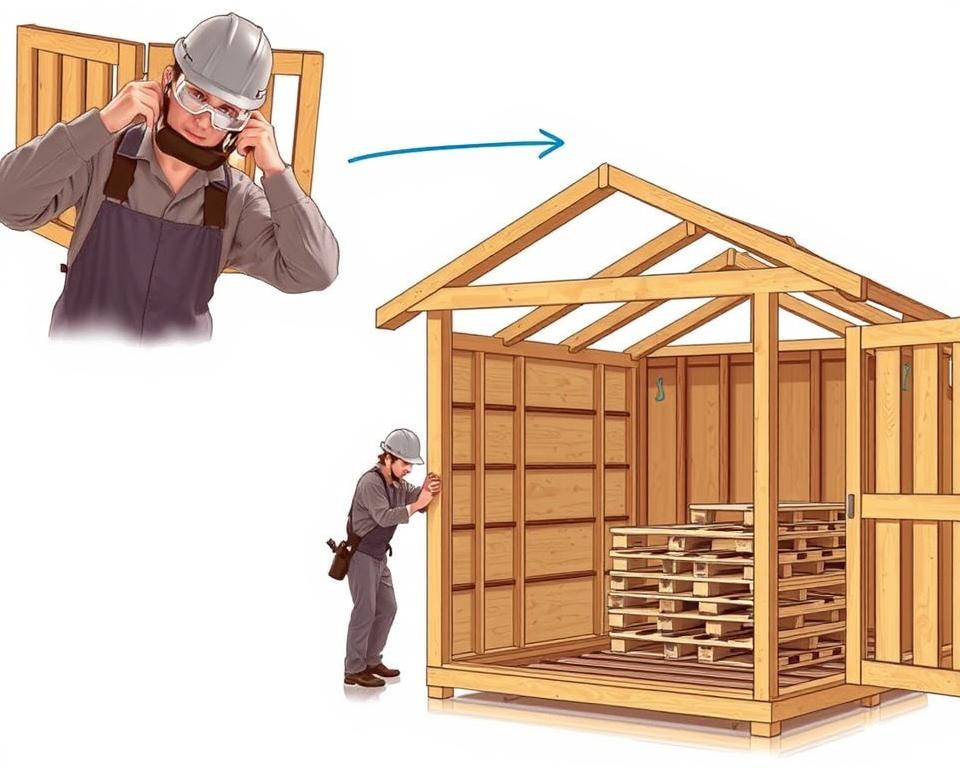

Wearing the Correct Protective Gear

Essential personal protective equipment forms the first line of defence. Thick work gloves prevent splinters and cuts from sharp edges. Safety glasses protect eyes from flying debris during disassembly.

A dust mask avoids inhaling particles, while steel-toed boots provide crucial foot protection. Proper care should extend to checking tools before use, as old equipment can cause accidents.

Handling Hazardous Materials Safely

Older structures present specific hazards like rusty nails and screws. These pose infection risks, making current tetanus vaccinations important. Workers should never stand on fragile roof panels when using ladders.

The serious health hazard of asbestos requires particular attention. This material was common in construction until 1999. If suspected, professional assessment and removal are strongly recommended.

All utilities must be disconnected before starting work. Maintaining clear pathways prevents trips and falls during material movement. Having assistance is crucial for managing heavy components safely.

Essential Tools and Equipment for the Task

The right equipment selection can transform a challenging task into a manageable process with proper preparation. Having all necessary items gathered before starting prevents frustrating work stoppages. This allows the project to proceed smoothly from beginning to end.

Basic Tools Overview: Hammer, Crowbar, and Screwdriver

The claw hammer serves as a fundamental piece of equipment. It drives out stubborn fixings and extracts nails from timber components. This versatile tool handles multiple functions efficiently.

Screwdrivers play a critical role in the dismantling process. Both manual adjustable types and powered alternatives prove valuable. An electric screwdriver or cordless drill with appropriate bits dramatically reduces effort.

Prising tools like crowbars and flat-head screwdrivers separate joined components effectively. They remove roof felt tacks and leverage apart warped sections. These tools provide the necessary force for stubborn connections.

Additional Equipment: Ladder, Drill and Safety Accessories

A stable, appropriately-sized ladder ensures safe roof access. Position it on level ground for maximum stability. Extension ladders may be necessary for taller structures.

Powered equipment options include cordless drills with various driver bits. While not essential, these tools significantly improve efficiency. They handle repetitive tasks with consistent results.

Safety accessories form an equally important part of the toolkit. Heavy-duty work gloves, safety glasses, and dust masks provide essential protection. These items are just as crucial as the dismantling tools themselves.

How to Dismantle a Shed: Step-by-Step Instructions

Executing the disassembly requires a clear, methodical sequence. This approach ensures the structure remains stable throughout the process, significantly reducing the risk of collapse.

Work begins at the top, removing all non-structural elements. Fascias, corner trims, and roof finials are taken off first. This preparatory step prevents damage and provides clear access to the main fixings.

Removing the Roof, Fascias and Trims

The roof dismantling is a critical phase. Start by carefully prising away the roofing felt; it may tear if old. Unscrew or extract nails from the roof boards systematically.

Have someone assist to prevent panels from sliding. Next, remove any ridge bars or brackets that connect the roof to the wall panels. Extreme caution is essential here as the structure becomes less stable.

Detaching Windows, Doors, Wall Panels and Floorboards

Carefully remove doors by unscrewing hinges or lifting out hinge pins. Set all hardware aside for potential reuse. Protect window panes by applying tape before unscrewing the frames to prevent glass from shattering.

For the walls, unscrew panels from the floor frame. Start with the front gable, removing screws from the corners. Tongue-and-groove or overlapped panels might separate into individual boards during this step.

- Clear away each section immediately, stacking materials neatly.

- Collect all screws and nails in a container to maintain a safe workspace.

- Constantly monitor the stability of the remaining framework.

Finally, address the floor. Identify how it is fixed—screws, bolts, or adhesive—and remove each fixing. Lift the floorboards or panels carefully. The base might be a single section that can be moved as one unit.

Managing Shed Components and Recycling Materials

Effective management of the disassembled components is a critical phase that demands as much attention as the physical removal work. A systematic approach to sorting the various materials streamlines the final cleanup and maximises opportunities for responsible disposal or reuse.

Sorting Wood, Metal, Glass and Other Parts

As each section of the structure comes down, immediate sorting pays significant dividends. Create designated areas for different parts: one stack for timber wood, another for metal fixtures, and a safe spot for glass panes.

This organised separation during the removal process prevents a tangled mess at the project’s end. It also makes transporting items to a recycling centre far more efficient.

Best Practices for Waste Disposal and Recycling

For larger projects, hiring a skip is a common solution. A four-yard unit typically costs between £150 and £200 for a week and suits an average garden shed.

Alternatively, taking materials to a local Household Waste Recycling Centre is effective. It is essential to confirm that the waste is from a domestic project, as DIY waste is often classified as ‘non-household’.

Many components have value beyond disposal. Usable timber, doors, and hardware can be sold or donated. However, materials like Perspex glazing require special handling as they are not accepted for standard recycling.

This responsible approach ensures valuable materials are kept out of landfill, benefiting both the environment and potentially the homeowner’s wallet.

Optimising Efficiency and Minimising Risks

Achieving peak productivity during the disassembly project hinges on a careful balance between speed and caution. The correct approach ensures the work progresses smoothly without compromising personal safety or material integrity.

Efficient Work Techniques and Time-saving Tips

The duration for this type of project is highly variable. It depends on the structure’s size, construction, and the worker’s experience. Rushing the process is a recipe for accidents and damaged materials.

Effective time management involves logical staging. Have all tools prepared and accessible before starting. Work during good weather and plan clear stopping points if the job spans multiple days.

For structures in confined spaces, pre-establish routes for moving components. Designate a specific stacking area that does not block access. This organisation is a safe and efficient way to manage the workspace.

Coordinating Team Efforts and Ongoing Safety Checks

Having at least one helper dramatically improves safety and halves the total work time. They provide essential support with heavy sections and enhance situational awareness.

Regular safety checks are crucial. Take breaks to assess progress and structural stability. Continuously collect loose fixings and clear debris to maintain a safe environment.

When encountering stubborn bolts or rusted fixtures, patience is key. Apply penetrating oil or use a hacksaw instead of forcing them. This careful method prevents injury and avoids damage.

| Aspect | Risk of Rushing | Benefit of Methodical Approach |

|---|---|---|

| Personal Safety | High risk of injuries | Minimised accident potential |

| Material Condition | Components likely damaged | Materials preserved for reuse |

| Overall Time | Often requires redoing work | Efficient, linear progression |

| Project Stress | High frustration levels | Controlled, manageable pace |

Conclusion

Completing the removal of an old garden structure marks the beginning of an exciting new chapter for your outdoor space. This guide has demonstrated that with careful planning, the right tools, and a focus on safety, this is an entirely achievable DIY project.

The cleared area offers a valuable blank canvas. Homeowners should take time to assess the existing base; a solid concrete foundation may be reusable, while a timber one likely needs replacing.

This project not only reclaims garden space but also provides a sense of accomplishment. The opportunity now exists to install a modern shed, create a patio, or simply enjoy the open area.

Responsibly recycling materials adds an environmental benefit. The experience gained is valuable knowledge for future garden improvements.

FAQ

What is the safest way to begin dismantling a garden shed?

The safest method is to start by removing any fragile parts, such as windows and glass panes. This prevents accidental breakage. Next, dismantle the roof structure before tackling the walls.

Which tools are essential for taking apart a wooden shed?

Essential tools include a claw hammer for nails, a pry bar or crowbar for leverage, and a screwdriver or power drill for screws. A sturdy ladder is also vital for safely reaching the roof.

How should one handle the disposal of an old shed?

It is best to sort materials into categories like wood, metal, and glass for recycling. Many local recycling centres accept these materials. This process supports environmental responsibility.

Can one person dismantle a shed, or is assistance necessary?

A> While a single person can manage a small structure, having a helper is strongly recommended. An extra pair of hands improves safety when handling large wall panels and roof sections.

What precautions should be taken with older sheds that might contain hazardous materials?

One should look for signs of asbestos in roofing or insulation, commonly found in sheds built before the year 2000. If suspected, consult a professional removal service to handle the hazardous materials safely.

How can one ensure the shed components remain intact for reuse?

Work slowly and methodically. Carefully remove screws and nails to avoid splitting the wood. Label each section as it is dismantled to simplify reassembly later.

What is the best approach for dealing with a concrete base during shed removal?

Once the shed structure is removed, the concrete base can be broken up using a sledgehammer. For larger bases, hiring a jackhammer might be more efficient. Check local guidelines for disposing of construction waste.