Is It Cheaper To Build Your Own Shed?

Many homeowners across the United Kingdom contemplate adding a garden structure. The question of constructing a personal storage solution versus buying a pre-made one is a common dilemma. This analysis explores the financial aspects of both choices.

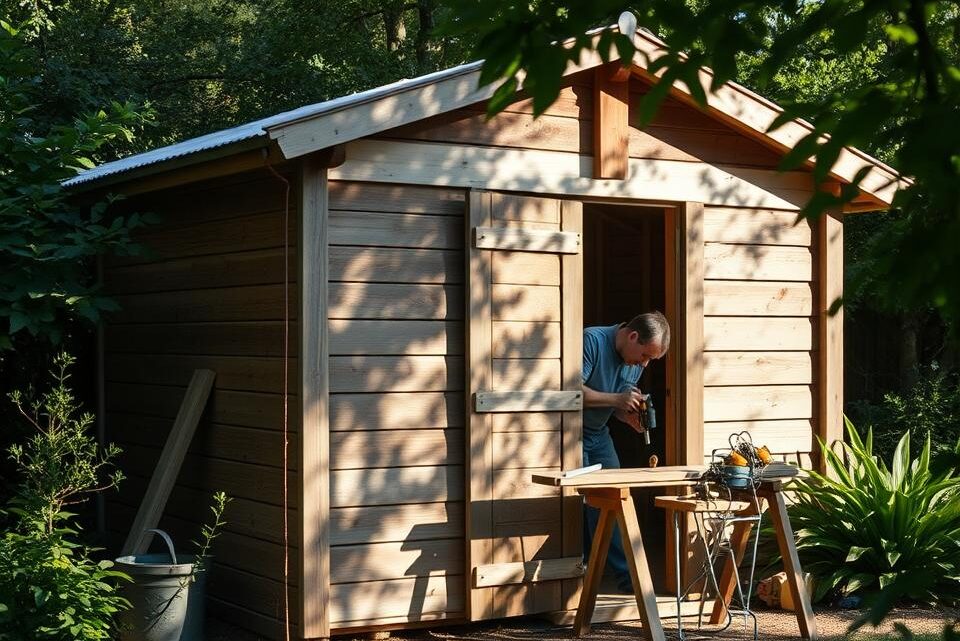

Creating a shed from scratch involves more than just material cost. It requires careful thought about time, necessary skills, and the project’s long-term durability. These factors significantly influence the final value proposition.

Whether for simple storage or a dedicated workshop space, understanding the full expense is crucial. This includes hidden outlays like tools, potential permits, and wood treatment. A thorough cost comparison provides clarity for this significant garden investment.

This guide offers detailed breakdowns and expert advice. It aims to help individuals decide if a diy project or a ready-made structure best suits their budget and capabilities. The goal is an informed decision for your property’s new addition.

Inhaltsverzeichnis

Key Takeaways

- Analysing the true cost involves both initial prices and hidden expenses.

- A diy approach to build a shed demands a significant investment of time and skill.

- Pre-made sheds offer convenience but may have limitations on customisation.

- The intended use, from basic storage to a functional space, influences the best choice.

- Long-term durability and maintenance requirements are critical considerations.

- This guide provides a comprehensive comparison to support your decision-making process.

Understanding the Cost Comparison

Property owners must weigh the advantages of custom construction against the convenience of ready-made structures. This comparison involves evaluating multiple factors beyond simple purchase price.

Overview of DIY vs. Pre-built Options

Homeowners have three primary choices when acquiring a garden storage solution. They can purchase a flat-pack kit, buy a fully assembled unit, or construct from raw materials.

Pre-built shed options provide significant convenience. These kit-based solutions arrive with pre-cut components and assembly instructions. The price spectrum ranges from £200 for basic plastic models to over £2,000 for premium wooden structures.

Key Considerations for UK Garden Projects

British weather and planning regulations significantly impact construction projects. Homeowners should consider regional material availability and weather patterns.

The decision to buy shed units or construct independently depends on multiple factors. These include available space, intended use, and personal skill level. The cheaper build options may not always provide the best long-term value.

Custom construction allows for tailored designs but requires more time and expertise. Pre-fabricated sheds offer predictability but limited customisation. Delivery and installation services can affect the total cost comparison significantly.

Detailed Breakdown of DIY and Pre-made Shed Costs

A precise financial analysis reveals the true investment for each path. The choice between a flat-pack kit and a from-scratch project involves weighing initial outlay against long-term value.

For a standard 6×4 foot structure, the price difference is clear. A retail shed might cost around £230. Constructing the same unit from raw materials totals approximately £306.

Material Costs and Tools

The materials list for a custom build includes structural timber, cladding, and roofing felt. Wood costs average £54.54 per cubic metre. Galvanised fixings and roof covering add to the total.

A solid foundation is crucial. The base cost varies from a simple timber frame to a poured concrete slab. Homeowners must also factor in tools. Essential equipment includes saws, drills, and measuring instruments.

For those without the necessary tools, rental or purchase adds to the project’s cost. A cement mixer, for example, can be hired for around £25 per day.

Labour, Construction Time and Assembly Costs

Professional assembly services for a small shed start from £160. A 6×4 unit takes an expert about four hours to build. This convenience comes at a price.

A DIY construction project requires significant time. An experienced builder might finish in one to two days. A novice could spend several weeks. This time investment represents a hidden cost.

For larger projects, like a 10×12 foot workshop, the costs shift. The materials for a custom build can be substantially lower than a flat-pack kit. This makes a self-build base a more attractive proposition for bigger garden structures.

Is It Cheaper To Build Your Own Shed?

The debate between self-construction and purchasing pre-made garden buildings centres on more than just immediate expenditure. Real-world examples demonstrate clear financial advantages for those willing to undertake the project themselves.

Pros of a DIY Build

Constructing a garden shed independently offers substantial savings. For a 10ft x 12ft structure, a flat-pack costs £2,333.20 while a custom-built option totals £1,609.15. This represents £724.05 in potential savings.

The cheaper build approach allows for superior material selection. Homeowners can choose higher-quality timber and more durable roofing materials. Customisation options include additional windows, insulation, and tailored dimensions.

Many find the sense of accomplishment from completing a diy project invaluable. The skills gained during construction provide long-term benefits beyond the immediate money saved.

Cons and Potential Hidden Costs

The time commitment required represents a significant consideration. Experienced builders might complete a shed in one to two days. Novices could spend several weeks on the same project.

Hidden expenses can reduce initial savings. Quality wood treatment costs approximately £50. Building permits range from £50-£200, with potential inspection fees adding £100-£200 more.

Unlike purchased structures with warranties, diy builds offer no guarantees. Future maintenance and repairs become the homeowner’s sole responsibility. This requires careful consideration before choosing the self-build route.

Factors Influencing Shed Costs in the UK

Several key elements determine the final expense of garden storage solutions in the United Kingdom. These variables extend beyond basic material costs and include regional differences, regulatory requirements, and project specifications.

Timber Price Fluctuations and Regional Variations

Forest Research UK documents significant timber price increases over recent years. Softwood sawlog costs now average £54.54 per cubic metre, affecting both DIY and pre-built sheds.

Geographical location plays a crucial role in material availability and pricing. Homeowners in remote areas often face higher delivery charges compared to urban centres with multiple suppliers.

The project’s size fundamentally impacts overall costs. Larger structures require more materials and potentially trigger planning permission requirements that smaller sheds avoid.

Permits, Insulation and Treatment Considerations

Planning permission regulations vary by local authority, with permits costing £50-£200 where required. Factors include shed height, boundary proximity, and intended use.

Insulation represents a substantial additional expense for year-round use. Converting structures into offices or workshops requires proper wall and ceiling insulation.

Treatment methods differ between professional and DIY approaches. Manufacturers use pressure treatment for approximately 10 years of protection, while DIY builders rely on surface-applied preservers costing around £50.

The level of finish significantly influences material selection and final cost. Premium cladding and roofing choices increase the budget, depending on the project’s size and complexity.

Budgeting and Planning Your Shed Project

Smart financial planning transforms garden construction projects from expensive endeavours to value investments. A well-structured budget accounts for all potential expenses while identifying areas for sensible savings.

Cost Saving Tips and Material Alternatives

Material selection presents significant opportunities to reduce expenditure. Choosing shiplap cladding over premium loglap can save approximately £100. OSB boarding works well for internal surfaces where appearance matters less.

The foundation represents another major cost variable. A timber frame on reclaimed slabs saves around £200 compared to solid concrete bases. Modern plastic grid systems offer another eco-friendly alternative at approximately £140.

| Foundation Type | Estimated Cost | Installation Time | Longevity |

|---|---|---|---|

| Solid Concrete Patio | £280+ | 2-3 days | Permanent |

| Timber Frame on Slabs | £80-£100 | 1 day | 10-15 years |

| Plastic Grid System | £140 | Half day | 20+ years |

Strategic purchasing through cashback websites can generate substantial returns. One builder earned over £1,100 on project purchases using TopCashback. Comparing prices across Wickes, B&Q, and local merchants ensures competitive material costs.

Alternative sourcing channels include eBay for cladding and Facebook Marketplace for windows. These options often provide quality materials at reduced prices. For kit shed buyers, selecting basic models and upgrading elements separately saves money.

Tool acquisition costs can be minimised through borrowing or hiring equipment. A comprehensive budget should include a 10-15% contingency fund for unexpected expenses. This approach helps homeowners save money while achieving their garden storage goals.

Expert Tips for DIY Shed Building

Expert builders consistently highlight that appropriate equipment choice significantly impacts project quality. Proper preparation separates successful garden constructions from disappointing outcomes. This guidance covers essential implements and required abilities.

Essential Tools and Required Skill Levels

A well-equipped workspace dramatically improves efficiency. The right implements ensure accurate cuts, secure fastenings, and safe working conditions. Beginners often overestimate the skill level needed for basic shed construction.

Most homeowners possess fundamental abilities for this type of project. Anyone comfortable assembling flat-pack furniture can manage a basic garden building. The table below outlines essential equipment and skill requirements.

| Tool Category | Essential Items | Skill Level Required | Alternative Options |

|---|---|---|---|

| Measuring | Tape measure, spirit level | Beginner | Laser level for precision |

| Cutting | Circular saw, utility knife | Intermediate | Hand saw for basic cuts |

| Fastening | Hammer, drill, screwdriver | Beginner | Impact driver for heavy duty |

| Safety | Gloves, goggles, ear protection | Essential | Dust mask for sanding |

Advice from Garden and Construction Experts

Professional builders emphasise foundation accuracy above all else. A level base prevents compounding errors throughout the construction process. Allow sufficient time for this critical first step.

Realistic scheduling prevents frustration. A basic 6×4 structure requires at least two full working days for experienced DIYers. Larger projects may span multiple weekends. Enlisting help reduces physical strain and construction time.

Follow a logical sequence: base preparation, floor frame, wall assembly, roof structure, then finishing touches. This systematic approach ensures structural integrity and efficient progress. Each stage offers skill development opportunities.

Conclusion

The journey to acquiring a functional garden structure presents homeowners with distinct pathways, each with unique benefits. Financial evidence clearly demonstrates that constructing independently offers substantial savings – from £78 for a 6×4 garden shed to over £700 for larger 10ft x 12ft buildings.

Beyond cost, diy projects deliver superior structural strength through better material selection. However, the decision involves weighing savings against time investment, skill level, and warranty considerations. Metal sheds provide low-maintenance alternatives but offer limited customisation.

The base and roof quality ultimately determine longevity, making these elements worthy investments regardless of construction method. Available space and intended storage needs should guide size decisions, with larger projects offering the greatest financial advantage.

Ultimately, purchased sheds provide convenience and protection, while building independently offers customisation and skill development. Each option serves different priorities effectively.

FAQ

What is the primary factor that determines if building a shed is cheaper?

The primary factor is the homeowner’s skill level and access to tools. For individuals with construction experience, a DIY project can offer significant savings on labour. However, those lacking skills may find the cost of materials and potential errors makes a pre-built garden shed a more economical choice.

How do material costs for a DIY shed compare to a pre-made kit?

Material costs for a DIY project can vary widely based on timber quality and design complexity. While sourcing materials independently can sometimes be cheaper, pre-made kits bundle everything needed, often at a competitive price. Fluctuations in timber prices can also affect this comparison.

Are there hidden costs associated with building your own shed?

Yes, potential hidden costs include purchasing or hiring specialised tools, acquiring building permits, and preparing a proper concrete or timber base. Mistakes during construction can also lead to wasted materials and additional expenses, which are not a factor with a pre-assembled option.

Does the size of the shed impact the cost-effectiveness of a DIY build?

A> Absolutely. Larger sheds require more materials and complex construction, increasing both the budget and time commitment. For a small, basic storage space, DIY can be very cost-effective. For larger garden sheds with features like windows or insulation, a kit might offer better value.

What are the key advantages of choosing a pre-built garden shed?

The main advantages are convenience and speed. Pre-built or flat-pack sheds arrive with all necessary components and clear instructions, eliminating the need for advanced woodworking skills. They also often come with guarantees and are constructed from treated timber for durability.

How important is the shed base to the overall project cost?

A proper base is crucial for the longevity of any shed, whether DIY or pre-made. The cost for a concrete slab or pressure-treated timber frame must be factored into the total budget. Neglecting this can lead to premature rot and damage, making it a necessary expense.

Can you save money by using alternative materials like metal for a DIY shed?

Metal sheds can be a cheaper alternative to timber, but they present different challenges. They often require different construction skills and tools for assembly. While the initial material price might be lower, metal sheds can be less versatile and may not offer the same aesthetic appeal as a wooden garden shed.