How to Light a Shed, Summerhouse or Log Cabin

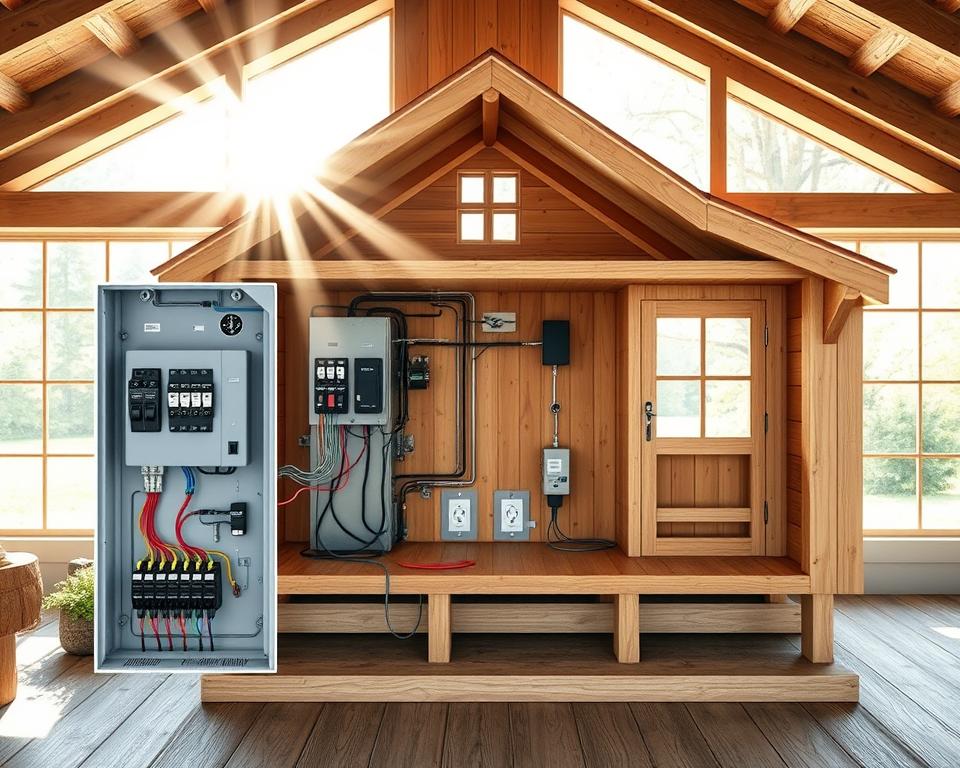

Transforming your garden building from a dark storage space into a functional and welcoming retreat starts with proper illumination. Whether you own a traditional wooden shed, an elegant summerhouse, or a cosy log cabin, the right outdoor building lighting can completely revolutionise how you use these spaces.

Many homeowners overlook the potential of their garden buildings simply because they lack adequate lighting. Proper electrical planning opens up endless possibilities for evening workshops, reading nooks, or entertaining guests in your outdoor sanctuary.

This comprehensive guide walks you through everything you need to know about illuminating your garden building safely and effectively. From understanding UK electrical regulations to choosing between mains-powered, solar, or battery-operated systems, we’ll cover the essential planning stages and installation processes.

You’ll discover practical solutions that suit your budget, building type, and intended use whilst ensuring compliance with British building standards and safety requirements.

Inhaltsverzeichnis

Key Takeaways

- Proper planning and electrical assessments are essential before installing any outdoor building lighting system

- UK building regulations require specific safety standards for garden building electrical installations

- Three main power options exist: mains electricity, solar panels, and battery-operated systems

- Professional electrical work may be required for mains-powered installations to ensure compliance

- LED lighting offers the most energy-efficient and long-lasting solution for outdoor buildings

- Weather-resistant fixtures and appropriate IP ratings are crucial for outdoor installations

Planning Your Outdoor Building Lighting Project

Before diving into your outdoor building lighting project, thorough preparation will save you time, money, and potential headaches. A well-planned shed electrical installation ensures optimal lighting performance whilst avoiding costly mistakes during the installation process.

Successful lighting projects begin with understanding your specific requirements. Consider whether you’ll use your space as a workshop requiring bright task lighting, or as a relaxation area needing softer ambient illumination. The planning phase also involves calculating power consumption, mapping cable routes, and ensuring compliance with electrical regulations.

Assessing Your Lighting Needs and Usage Patterns

Understanding how you’ll use your outdoor building determines your lighting requirements. Different activities demand varying light levels and types of illumination.

Start by listing all activities you’ll perform in the space. Workshop tasks like woodworking or repairs require bright, focused lighting of at least 500 lux. Reading areas need moderate lighting around 200-300 lux. Social spaces benefit from adjustable ambient lighting ranging from 50-150 lux.

Consider your usage patterns throughout the year. Will you primarily use the space during winter evenings when natural light is limited? Summer usage might require less artificial lighting due to longer daylight hours. Seasonal variations significantly impact your lighting strategy and energy consumption.

Think about safety requirements too. Pathways to your building need adequate illumination to prevent accidents. Emergency lighting might be necessary if you store valuable items or use the space frequently after dark.

Measuring Your Space and Power Requirements

Accurate measurements form the foundation of your lighting plan. Start by measuring the internal dimensions of your building, noting ceiling height, window positions, and any obstacles like beams or storage areas.

Calculate the total floor area to determine your lighting load. As a general rule, allow 10-15 watts per square metre for LED lighting in workshop spaces, or 5-8 watts per square metre for general illumination. These figures help estimate your total power consumption.

Document the distance from your main electrical supply to the building. This measurement affects cable sizing, voltage drop calculations, and installation costs. Distances over 30 metres often require larger cable sizes or intermediate distribution boards.

Consider future expansion needs. Installing slightly larger cables and consumer units initially costs less than upgrading later. Plan for additional circuits if you might add power sockets, heating, or security systems in future.

Creating a Comprehensive Lighting Layout Plan

A detailed lighting layout plan guides your installation and helps calculate material requirements accurately. Begin by sketching your building’s floor plan, marking windows, doors, and fixed features.

Position light fittings to eliminate shadows in work areas. Avoid placing lights directly above where you’ll stand, as this creates shadows on your work surface. Instead, position fittings to provide cross-illumination from multiple angles.

Plan switch locations for convenience and safety. Switches should be easily accessible from entrances and positioned where you can reach them without walking through dark areas. Consider two-way switching for buildings with multiple entrances.

| Building Type | Recommended Light Level (Lux) | Typical Power Requirement | Switch Configuration |

|---|---|---|---|

| Workshop Shed | 500-750 | 12-15W per m² | Two-way switching recommended |

| Storage Shed | 150-200 | 5-8W per m² | Single switch near entrance |

| Summerhouse | 100-300 | 8-12W per m² | Multiple zones with dimmers |

| Log Cabin Office | 300-500 | 10-14W per m² | Task and ambient circuits |

Mark cable routes on your plan, avoiding areas where you might drill or fix items later. Plan routes that minimise cable lengths whilst maintaining safe clearances from water sources and high-traffic areas.

Include a materials list with your plan. This should specify cable types, light fittings, switches, and protective devices required. Having a comprehensive list prevents multiple trips to suppliers and ensures you don’t forget essential components during installation.

Understanding Electrical Requirements for Outdoor Structures

Navigating electrical regulations might seem complex, but mastering the basics protects your investment and ensures safety. Getting your summerhouse wiring project right involves understanding UK building regulations, choosing appropriate power supplies, and knowing when to call in professional help.

Proper electrical planning prevents costly mistakes and dangerous installations. Whether you’re lighting a garden shed or installing comprehensive electrical systems in a log cabin, compliance with safety standards remains paramount.

UK Electrical Regulations and Part P Compliance

Part P of the Building Regulations governs electrical safety in domestic properties, including outdoor buildings. This legislation requires notification to Building Control for most electrical work in gardens and outdoor structures.

Notifiable work includes new electrical circuits, consumer unit installations, and any work in special locations. However, simple additions like extra sockets or lights on existing circuits often fall outside notification requirements.

The purpose of Part P is to reduce the number of deaths, injuries and fires caused by defective electrical installations in homes.

Understanding these regulations helps you plan your project correctly. Non-notifiable work can save time and money, whilst notifiable projects require either professional installation or self-certification through approved schemes.

| Work Type | Notification Required | Who Can Do It | Certification Needed |

|---|---|---|---|

| Adding lights to existing circuit | No | Competent DIYer | Minor works certificate |

| New outdoor circuit installation | Yes | Registered electrician | Installation certificate |

| Consumer unit replacement | Yes | Qualified professional | Installation certificate |

| Socket additions on existing circuit | No | Competent DIYer | Minor works certificate |

Power Supply Options and Distance Considerations

Distance between your house and outdoor building significantly affects your power supply choices. Short runs under 20 metres often allow simple circuit extensions, whilst longer distances may require dedicated consumer units.

Armoured cable provides the most reliable outdoor power transmission. Steel wire armoured (SWA) cable protects against physical damage and moisture ingress, making it ideal for buried or exposed installations.

Voltage drop calculations become crucial for longer cable runs. Standard domestic circuits lose voltage over distance, potentially causing lights to dim or equipment to malfunction.

Three main power supply options exist for outdoor buildings:

- Circuit extension – Extending existing house circuits for basic lighting needs

- Sub-main installation – Running a larger cable to supply multiple circuits

- Separate consumer unit – Installing independent electrical distribution in the building

Your choice depends on power requirements, distance, and intended use. A simple garden shed might need only basic lighting, whilst a workshop summerhouse requires multiple sockets and higher power capacity.

When Professional Electrical Work is Required

Certain electrical tasks always require qualified professionals, regardless of your DIY skills. Safety regulations exist to protect lives and property, making professional involvement essential for complex installations.

New consumer unit installations must be completed by registered electricians. These professionals possess the qualifications and insurance necessary for such critical safety equipment.

Underground cable installations often require professional expertise. Proper burial depths, route planning, and connection methods ensure long-term safety and reliability.

Consider professional help when:

- Installing new circuits requiring Building Control notification

- Working with three-phase power supplies

- Connecting to the main electrical panel

- Planning complex lighting control systems

Professional electricians provide certification, insurance coverage, and guarantee their work. This protection often outweighs the additional cost, particularly for substantial summerhouse wiring projects.

Many electricians offer consultation services to help plan your project. They can advise on regulations, suggest cost-effective solutions, and identify which elements you can safely tackle yourself.

Choosing the Right Lighting Solutions for Your Building

Modern lighting technology offers numerous solutions for illuminating sheds, summerhouses, and log cabins effectively. Each option brings distinct advantages and considerations that can significantly impact your project’s success. Understanding these differences helps you make an informed decision that matches your specific requirements and budget.

The key factors to consider include energy efficiency, installation complexity, running costs, and maintenance requirements. Your choice will also depend on whether you have access to mains electricity or prefer off-grid solutions. Let’s explore the main lighting technologies available for outdoor buildings.

LED Strip Lights and Panel Systems

LED strip lights have revolutionised outdoor building illumination with their exceptional energy efficiency and versatility. These flexible lighting solutions consume up to 80% less energy than traditional bulbs whilst lasting significantly longer. You can easily cut LED strips to exact lengths and install them around corners, making them perfect for awkward spaces.

LED panel systems provide uniform, bright illumination across large areas. They work exceptionally well in workshops or storage areas where consistent lighting is essential. Most LED panels offer excellent colour rendering, making detailed work more comfortable and safer.

The main advantages include low heat output, instant illumination, and minimal maintenance requirements. However, quality varies significantly between manufacturers, so investing in reputable brands ensures longevity and consistent performance.

Solar-Powered and Battery-Operated Options

Solar lighting systems offer complete independence from mains electricity, making them ideal for remote locations or temporary installations. Modern solar panels charge efficiently even in overcast conditions, though performance varies seasonally in the UK climate.

Battery-operated LED lights provide immediate illumination without any wiring. Rechargeable options with USB charging have become increasingly popular for occasional use buildings. These systems work brilliantly for emergency lighting or infrequent access situations.

The limitations include reduced brightness during winter months and the need for regular battery maintenance. Solar systems require unobstructed panel positioning, which isn’t always possible in shaded garden locations.

Mains-Powered Lighting Systems

Traditional mains-powered systems deliver consistent, reliable illumination regardless of weather conditions. These systems support higher wattage fixtures and multiple lighting circuits, making them suitable for comprehensive log cabin power supply installations.

Mains electricity enables you to power additional equipment like heaters, power tools, or security systems alongside your lighting. The infrastructure investment pays dividends if you plan to use your building regularly or for extended periods.

Professional installation ensures compliance with electrical regulations and safety standards. The initial costs are higher, but running costs remain predictable with no battery replacements or solar panel cleaning required.

Smart Lighting and Control Systems

Smart lighting technology brings unprecedented convenience and energy savings to outdoor buildings. These systems allow smartphone control, automated scheduling, and integration with security systems. You can adjust brightness levels, set timers, and monitor energy consumption remotely.

Motion sensors automatically activate lights when you enter your building, whilst daylight sensors prevent unnecessary daytime operation. Smart switches can control traditional fixtures, making upgrades straightforward without rewiring.

Many smart systems work with both mains-powered and low-voltage installations. The technology integrates seamlessly with existing log cabin power supply setups, adding modern functionality without major infrastructure changes.

Consider your long-term usage patterns and expansion plans when selecting lighting solutions. A well-chosen system grows with your needs whilst providing years of reliable service. The investment in quality components and proper installation pays dividends through reduced maintenance and enhanced functionality.

Essential Tools and Materials for Installation

Proper preparation with the correct tools and materials ensures your garden building electricity project succeeds from start to finish. Having everything you need before beginning work prevents frustrating delays and helps maintain safety standards throughout the installation process. Professional electricians know that thorough preparation is the key to efficient and safe electrical work.

This comprehensive guide covers all the essential equipment you’ll need for your outdoor building electrical installation. From basic hand tools to specialised electrical components, we’ll ensure you’re properly equipped for success.

Basic Tools and Equipment Checklist

Every garden building electricity installation requires a solid foundation of basic tools. These essential items form the backbone of your toolkit and will be used throughout the project.

Hand tools are your primary workhorses during installation. You’ll need a variety of screwdrivers, including both flathead and Phillips head types in different sizes. Wire strippers are absolutely essential for preparing cable connections safely and efficiently.

A good quality drill with masonry and wood bits will help you create clean holes for cable entry points. Measuring tools such as a tape measure and spirit level ensure accurate positioning of fixtures and components.

Specialised electrical tools make the job much easier. A multimeter helps you test circuits and verify connections. Cable detectors prevent accidentally drilling into existing wiring. Conduit benders allow you to create neat, professional-looking cable runs.

- Torch or headlamp for working in dark spaces

- Knife or cable stripping tool

- Pliers and side cutters

- Adjustable spanner set

- Hole saw attachments for clean cable entry

Electrical Components and Weatherproof Fittings

Selecting appropriate electrical components is crucial for a safe and reliable garden building electricity system. Quality components designed for outdoor use will provide years of trouble-free service in challenging weather conditions.

Cable selection depends on your power requirements and installation distance. Twin and earth cable is standard for most domestic installations, whilst armoured cable provides extra protection for underground runs. Always choose cable rated for outdoor use with appropriate current capacity.

Junction boxes and consumer units must have suitable IP ratings for outdoor environments. IP65-rated enclosures provide excellent protection against dust and water ingress. Weatherproof switches and sockets ensure safe operation in all conditions.

The following table shows recommended IP ratings for different garden building electricity components:

| Component Type | Minimum IP Rating | Typical Applications | Additional Protection |

|---|---|---|---|

| External Junction Boxes | IP65 | Cable connections outdoors | Weatherproof gaskets |

| Consumer Units | IP54 | Main distribution board | Lockable enclosure |

| Light Switches | IP44 | Internal wall mounting | Splash-proof covers |

| External Sockets | IP66 | Power outlets outside | Spring-loaded covers |

| Light Fittings | IP54 | Ceiling and wall lights | Sealed lamp holders |

Circuit protection devices including RCDs and MCBs must be correctly rated for your installation. 30mA RCD protection is mandatory for all socket circuits in outdoor buildings. Choose quality brands that meet British Standards for reliability and safety.

Safety Equipment and Protective Gear

Working safely with electricity requires proper protective equipment at all times. Personal protective equipment protects you from electrical hazards and physical injury during installation work.

Safety glasses protect your eyes from flying debris when drilling or cutting. Insulated tools provide an extra layer of protection when working near live circuits. A voltage tester is essential for confirming circuits are dead before starting work.

Protective clothing should include sturdy work boots with rubber soles and close-fitting garments that won’t catch on equipment. Never work on electrical installations while wearing loose jewellery or clothing that could create safety hazards.

Essential safety equipment includes:

- Voltage tester or proving unit

- Insulated screwdrivers and tools

- Safety glasses or goggles

- Work gloves for handling materials

- First aid kit for emergencies

A lockout/tagout kit helps ensure circuits remain isolated during work. Warning signs and barriers prevent others from accidentally interfering with your installation. Proper planning and safety equipment make every garden building electricity project safer and more professional.

Remember that some electrical work requires notification to Building Control or certification by a qualified electrician. Always check local regulations before beginning your installation project.

How to Light a Shed, Summerhouse or Log Cabin: Complete Installation Guide

This comprehensive installation guide takes you through each critical step of creating a professional weatherproof lighting system for your outdoor building. The installation process requires methodical planning and careful execution to ensure safety and reliability. Each stage builds upon the previous one, creating a systematic approach that minimises risks and maximises results.

Following these detailed procedures ensures your lighting system meets UK electrical regulations whilst providing years of dependable service. The key to successful installation lies in thorough preparation and attention to detail at every stage.

| Installation Step | Key Activities | Safety Priority | Time Required |

|---|---|---|---|

| Safety Preparations | Power isolation, risk assessment, equipment check | Critical | 30-45 minutes |

| Cable Route Planning | Measuring, marking routes, entry point preparation | High | 1-2 hours |

| Electrical Supply Installation | Consumer unit mounting, RCD installation, earthing | Critical | 2-3 hours |

| Cable Running & Fittings | Cable installation, light fitting mounting, connections | High | 3-4 hours |

| Testing & Commissioning | Electrical testing, system verification, documentation | Critical | 1 hour |

Safety Preparations and Power Isolation

Begin your weatherproof lighting installation by conducting a thorough risk assessment of your work area. Check weather conditions and ensure you have adequate daylight or temporary lighting for safe working. Never attempt electrical work in wet conditions or during adverse weather.

Isolate the main power supply at your property’s consumer unit by switching off the relevant circuit breaker. Always test the circuit with a voltage tester to confirm power isolation before proceeding. Lock off the circuit breaker and inform all household members about the ongoing electrical work.

Prepare your workspace by clearing access routes and organising tools systematically. Ensure you have adequate ventilation if working inside the building. Set up proper lighting for the work area using battery-powered LED work lights.

Planning Cable Routes and Entry Points

Map out the most efficient cable routes from your main electrical supply to the outdoor building. Consider the shortest practical distance whilst avoiding obstacles like driveways, pathways, and existing utilities. Underground cable routes typically prove most reliable for weatherproof lighting installations.

Mark cable entry points on both your house and outdoor building using chalk or removable markers. Entry points should be positioned to minimise water ingress whilst allowing easy cable access. Plan for appropriate cable protection through walls using suitable conduit or trunking.

Measure cable runs accurately, adding 10% extra length for connections and routing flexibility. Record these measurements for material ordering and future reference. Consider future expansion needs when planning your cable routes.

Installing Electrical Supply and Consumer Unit

Mount the consumer unit inside your outdoor building at an appropriate height, typically 1.2-1.5 metres from floor level. Choose a location that provides easy access whilst protecting the unit from moisture and physical damage. Ensure adequate clearance around the unit for maintenance access.

Install the main switch and RCD protection according to manufacturer specifications. The RCD must be rated appropriately for your weatherproof lighting circuit load and provide 30mA sensitivity for personal protection. Connect the earthing system to the building’s main earth terminal.

Prepare cable entry points by drilling appropriate holes and fitting weatherproof cable glands. Seal around cable entries using suitable weatherproof compound to prevent moisture ingress. Install cable support brackets at regular intervals along the cable route.

Running Cables and Installing Light Fittings

Run your supply cable from the main building to the outdoor structure using appropriate cable protection methods. Underground runs require armoured cable or cable in protective ducting, buried to the correct depth with warning tape above. Overhead runs need proper support and adequate clearance heights.

Install light fittings according to manufacturer instructions, ensuring all connections are made within appropriate junction boxes or connection points. Weatherproof lighting fittings must achieve the correct IP rating for their location and exposure conditions.

Route internal wiring neatly using appropriate cable clips or conduit systems. Maintain proper spacing between cables and avoid sharp bends that could damage cable insulation. Label all circuits clearly at the consumer unit for future identification.

Making Connections and Testing the System

Make all electrical connections using appropriate connectors and junction boxes rated for outdoor use. Ensure all connections are tight and properly insulated to prevent moisture ingress and electrical faults. Double-check all connections against your wiring diagram before energising the system.

Conduct comprehensive electrical testing using appropriate test equipment. Test insulation resistance, earth continuity, and RCD operation according to current regulations. Record all test results for certification purposes and future reference.

Energise the system gradually, testing each circuit individually before connecting the complete weatherproof lighting installation. Verify that all lights operate correctly and that switching arrangements function as intended. Check that emergency isolation procedures work effectively.

Weatherproofing and Safety Considerations

Garden building electrical systems face constant exposure to moisture, temperature fluctuations, and environmental hazards that demand specialised protection measures. Unlike indoor installations, outdoor lighting must withstand rain, snow, humidity, and extreme temperature variations whilst maintaining safe operation year-round. Understanding these challenges helps you select appropriate components and installation methods that ensure long-term reliability.

British weather conditions create particular challenges for outdoor electrical installations. Your lighting system must cope with everything from summer heat waves to winter freeze-thaw cycles. Proper weatherproofing isn’t just about preventing immediate failures—it’s about ensuring your investment continues working safely for years to come.

IP Ratings and Moisture Protection Requirements

IP (Ingress Protection) ratings provide a standardised way to understand how well electrical equipment resists dust and moisture penetration. These two-digit codes tell you exactly what level of protection each component offers. The first digit indicates dust protection, while the second shows moisture resistance levels.

Different areas of your garden building require different protection levels. Areas directly exposed to rain need higher ratings than sheltered internal spaces. Choosing the wrong IP rating can lead to premature failure and safety hazards.

| Location | Minimum IP Rating | Protection Level | Typical Applications |

|---|---|---|---|

| External walls | IP65 | Dust tight, water jet protection | External LED outdoor lights, junction boxes |

| Under eaves | IP44 | Solid object protection, splash proof | Sheltered light fittings, switches |

| Internal dry areas | IP20 | Finger protection, no water protection | Internal switches, standard fittings |

| Damp internal areas | IP54 | Limited dust ingress, splash protection | Areas prone to condensation |

Temperature cycling poses another significant challenge. Materials expand and contract with temperature changes, potentially creating gaps in seals. High-quality weatherproof fittings include gaskets and seals designed to maintain protection through these cycles.

Condensation can form inside poorly sealed fittings when warm, moist air meets cold surfaces. This internal moisture can be just as damaging as external water ingress. Look for fittings with breathing membranes that allow pressure equalisation whilst maintaining water resistance.

RCD Protection and Earthing Systems

Residual Current Device (RCD) protection is legally required for all outdoor electrical installations in the UK. These life-saving devices monitor electrical current flow and instantly disconnect power when they detect dangerous earth leakage. RCD protection can prevent fatal electric shocks and reduce fire risks.

Your garden building installation requires a 30mA RCD for final circuit protection. This sensitive setting detects even small earth leakage currents that could indicate damaged cables or moisture ingress. The RCD must be tested monthly using the built-in test button to ensure continued protection.

“RCD protection has prevented thousands of electrical accidents since becoming mandatory. It’s not just about compliance—it’s about protecting lives and property.”

Earthing systems provide a safe path for fault currents and help RCDs operate correctly. Your garden building must connect to the main house earthing system through the supply cable. All exposed metalwork, including light fittings and cable trunking, requires earthing connections.

TT earthing systems may be necessary where the supply cable doesn’t include an earth conductor. This involves installing a local earth electrode and requires additional RCD protection at 100mA for the entire installation. Professional assessment determines the most appropriate earthing arrangement for your specific situation.

Equipotential bonding connects exposed metalwork to prevent dangerous voltage differences during fault conditions. In garden buildings, this includes metal door frames, window frames, and any structural steelwork. Proper bonding ensures all metalwork rises to the same potential during faults.

Fire Safety and Ventilation Considerations

Fire safety becomes critically important in wooden garden buildings where electrical faults could have devastating consequences. Heat generation from lighting systems, particularly older technologies, can create fire risks if not properly managed. Modern LED outdoor lights generate significantly less heat than traditional alternatives, reducing these risks.

Adequate ventilation prevents heat buildup around electrical components. Even low-heat LED systems benefit from air circulation to maintain optimal operating temperatures. Overheating reduces component lifespan and can create fire hazards in extreme cases.

Cable routing requires careful planning to avoid heat traps and potential ignition sources. Cables should never run through insulation without proper protection, as trapped heat can degrade cable insulation. Use appropriate cable clips and trunking to maintain safe separation from combustible materials.

Electrical accessories must be suitable for wooden structures. Standard domestic accessories may not provide adequate protection in timber buildings. Look for accessories with higher temperature ratings and improved fire resistance properties.

Emergency isolation switches should be easily accessible from outside the building. This allows quick power disconnection in emergency situations without entering a potentially dangerous structure. Position the main isolator switch near the building entrance in a clearly marked, weatherproof enclosure.

Regular inspection schedules help identify potential fire hazards before they become dangerous. Check for signs of overheating, damaged cables, or loose connections during routine maintenance visits. Early detection and prompt repairs prevent small problems from becoming major safety hazards.

Specific Installation Techniques for Different Buildings

Understanding building-specific wiring methods ensures your electrical installation complements your structure’s design. Each type of outdoor building presents distinct construction characteristics that influence how you route cables, position fittings, and achieve professional results.

The key to successful installation lies in working with your building’s natural features rather than against them. This approach not only creates neater installations but also maintains structural integrity and weather protection.

Wooden Shed Electrical Installation Methods

Traditional wooden sheds offer the most straightforward electrical installation opportunities. The timber frame construction provides natural routing channels between wall studs and roof rafters.

Start by identifying the main structural timbers using a stud finder. Plan your cable runs to follow these vertical and horizontal supports wherever possible. This approach keeps wiring neat and avoids weakening the shed’s structure.

For cable entry points, drill holes at a slight downward angle to prevent water ingress. Use weatherproof cable glands and seal around them with exterior-grade silicone. Position these entry points away from door hinges and window frames to avoid future access issues.

“The secret to professional shed wiring is making the installation invisible whilst maintaining easy access for future maintenance.”

Surface-mounted systems work particularly well in sheds where aesthetics are less critical than functionality. Use plastic trunking to protect cables and create neat runs along walls and ceiling edges.

Summerhouse Wiring and Finishing Techniques

Summerhouses typically feature higher-quality construction with insulation and interior finishing. This creates opportunities for concealed wiring systems that maintain the building’s attractive appearance.

Before installation, check whether your summerhouse has cavity walls or solid construction. Cavity walls allow cables to run within the wall space, whilst solid walls require surface mounting or routing through specially created channels.

For insulated buildings, run cables behind the insulation layer before fitting interior cladding. This technique keeps all wiring completely hidden whilst maintaining thermal performance.

Consider solar shed lighting systems for summerhouses in remote locations. These systems eliminate the need for mains electrical supply whilst providing adequate illumination for most uses.

Plan switched lighting circuits to complement the summerhouse’s intended use. Multiple switching points work well for larger buildings, allowing control from both entrance and seating areas.

Log Cabin Electrical System Integration

Log cabins present unique opportunities and challenges for electrical installation. The thick timber walls provide excellent concealment possibilities but require careful planning for cable routing and connection access.

Traditional log construction uses interlocking horizontal logs with gaps that can accommodate electrical cables. Plan your installation during construction if possible, as retrofitting can prove more challenging.

For existing log cabins, use the natural gaps between logs to route cables horizontally. Vertical runs typically require drilling through the log structure or using external conduit systems.

| Building Type | Best Wiring Method | Key Considerations | Typical Installation Time |

|---|---|---|---|

| Wooden Shed | Surface-mounted trunking | Structural timber locations | 4-6 hours |

| Summerhouse | Concealed cavity wiring | Insulation and finishing | 6-8 hours |

| Log Cabin | Inter-log cable routing | Log joint accessibility | 8-12 hours |

| Solar Systems | External panel mounting | Panel positioning and battery location | 3-4 hours |

Access panels become particularly important in log cabin installations. Install discrete access hatches at key connection points to allow future maintenance without dismantling the structure.

The thermal mass of log construction affects electrical components differently than lightweight timber buildings. Allow adequate ventilation around transformers and control equipment to prevent overheating.

For remote log cabins, solar shed lighting systems offer excellent value. The robust construction provides secure mounting points for solar panels, whilst the building’s thermal mass helps regulate battery temperatures.

Consider future expansion when planning log cabin electrical systems. The substantial construction can accommodate heavier electrical loads than typical garden buildings, making provision for additional circuits worthwhile.

Installing Alternative Lighting Systems

Not every outdoor building project needs a traditional electrical connection to achieve professional lighting results. Alternative lighting systems have transformed how we illuminate sheds, summerhouses, and log cabins. These innovative solutions offer simplified installation processes whilst delivering excellent performance and environmental benefits.

Modern alternative lighting technologies provide remarkable flexibility for outdoor structures. They eliminate the need for complex wiring whilst maintaining compliance with electrical safety regulations. These systems prove particularly valuable for buildings located far from main power supplies or temporary installations.

Solar Lighting Setup and Panel Positioning

Solar lighting systems represent the most environmentally sustainable option for outdoor building illumination. These systems harness natural sunlight during daylight hours to power LED lights throughout the evening. Modern solar panels deliver impressive efficiency rates even in Britain’s variable climate conditions.

Optimal panel positioning requires careful consideration of your building’s orientation and surrounding obstacles. South-facing installations typically provide maximum energy capture throughout the year. Position panels at angles between 30-45 degrees for optimal performance in UK latitudes.

Battery sizing plays a crucial role in system reliability during winter months. Calculate your daily energy requirements and multiply by five to ensure adequate power storage. Quality lithium batteries offer superior performance compared to traditional lead-acid alternatives, lasting significantly longer in outdoor conditions.

| Solar System Component | Typical Capacity | Installation Location | Maintenance Requirements |

|---|---|---|---|

| Solar Panel | 20-100 watts | South-facing roof | Quarterly cleaning |

| Battery Storage | 12V 50-200Ah | Protected interior space | Annual capacity check |

| LED Light Fittings | 5-20 watts each | Interior ceiling/walls | Minimal maintenance |

| Charge Controller | 10-30 amp MPPT | Dry interior location | Visual inspection monthly |

Installation requires minimal technical expertise whilst maintaining full compliance with electrical safety regulations. Most solar lighting systems operate at safe low voltages, typically 12V or 24V DC. This eliminates many hazards associated with mains voltage installations.

Low-Voltage LED System Installation

Low-voltage LED systems offer exceptional safety advantages whilst delivering brilliant illumination quality. These systems typically operate at 12V or 24V, significantly reducing electrical hazards during installation and maintenance. The reduced voltage requirements make them ideal for DIY enthusiasts seeking professional results.

Transformer selection forms the foundation of any low-voltage system. Choose transformers rated at least 20% above your total LED load to ensure reliable operation. Electrical safety regulations require proper earthing and RCD protection even for low-voltage installations in outdoor buildings.

Cable sizing becomes critical for low-voltage systems due to voltage drop considerations. Longer cable runs require larger conductor sizes to maintain adequate voltage at the light fittings. Use specialised low-voltage cables designed for outdoor applications to ensure longevity and performance.

LED strip lights provide versatile lighting solutions for various applications. Install them behind diffusers or within aluminium channels for professional appearances. These systems offer excellent energy efficiency whilst producing minimal heat, making them perfect for wooden structures.

Control systems can include dimming capabilities, timer functions, and motion sensors. Modern low-voltage controllers integrate seamlessly with smart home systems. This allows remote operation and scheduling whilst maintaining compliance with electrical safety regulations.

Battery-Powered and Rechargeable Light Solutions

Battery-powered lighting systems deliver ultimate installation flexibility without any permanent electrical connections. These solutions prove perfect for occasional-use buildings or situations where electrical installation isn’t practical. Modern rechargeable systems offer impressive runtime and reliability.

Lithium-ion technology has revolutionised portable lighting capabilities. Quality battery lights now provide 8-12 hours of illumination from single charges. Some advanced systems include USB charging ports, making them multifunctional power sources for outdoor buildings.

Strategic placement maximises lighting effectiveness whilst minimising the number of units required. Consider motion-activated systems for energy conservation and convenience. These intelligent systems activate automatically when you enter the building, providing instant illumination without manual switching.

Rechargeable LED lanterns offer traditional aesthetics with modern efficiency. Many models include multiple brightness settings and emergency features. Some incorporate solar panels for autonomous recharging, combining battery convenience with renewable energy benefits.

Magnetic mounting systems enable quick fixture repositioning as your needs change. This flexibility proves particularly valuable for workshops or storage areas where lighting requirements vary seasonally. Quality magnetic mounts provide secure attachment to metal surfaces whilst allowing easy removal.

Timer controls and smart switching systems rival traditional mains-powered installations in sophistication. Modern battery-powered lights can integrate with smartphone apps for remote control and scheduling. These features ensure your outdoor building remains well-lit whilst optimising battery life through intelligent power management.

Maintenance requirements remain minimal compared to traditional electrical systems. Regular battery replacement or recharging represents the primary ongoing requirement. This simplicity makes alternative lighting systems particularly attractive for remote locations or buildings with infrequent access.

Testing, Certification and Compliance

Completing your shed, summerhouse, or log cabin lighting installation requires meticulous testing and official documentation to meet UK standards. Many DIY enthusiasts overlook this crucial final step. However, proper testing and certification protect your investment and ensure legal compliance.

The testing phase verifies that your electrical work is safe and functional. It also provides essential documentation for insurance purposes and future property sales. Without proper certification, your installation may not meet building regulations or insurance requirements.

Understanding the complete testing and certification process gives you confidence in your installation’s safety and legality. This knowledge also helps you maintain compliance throughout your system’s operational life.

Electrical Installation Testing Procedures

Professional electrical testing follows a systematic approach to verify installation safety and performance. These tests identify potential hazards before they become dangerous problems. Each test serves a specific purpose in confirming your installation meets safety standards.

Continuity testing checks that protective conductors and circuit protective conductors are properly connected. This test uses a low-resistance ohmmeter to measure resistance between connection points. Readings should typically be less than 0.05 ohms for effective earthing.

Insulation resistance testing measures the quality of insulation between live conductors and earth. The test applies 500V DC for installations up to 500V AC supply. Minimum acceptable readings are 1 megohm for most domestic installations.

Key testing procedures include:

- Visual inspection of all connections and IP rated fittings

- Continuity testing of protective conductors

- Insulation resistance measurements

- Polarity verification at all outlets

- RCD functionality and tripping time tests

- Earth fault loop impedance testing

RCD testing confirms that residual current devices operate within specified time limits. The test simulates earth leakage conditions to verify protective disconnection occurs. Proper RCD function is essential for outdoor installations where moisture risks are higher.

Earth fault loop impedance testing ensures adequate fault current flows to operate protective devices. This test measures the complete path from the supply transformer through your installation and back. Results must fall within acceptable limits for your protective device ratings.

Building Control Notification Requirements

UK building regulations require notification for most electrical work in domestic properties. Part P of the Building Regulations covers electrical safety in dwellings and associated outbuildings. Your shed, summerhouse, or log cabin likely falls under these requirements.

Notifiable electrical work includes new circuits and additions to existing installations. Installing lighting circuits in outdoor buildings typically requires Building Control notification. The notification must occur before work commences or within specified timeframes.

Two notification routes are available:

- Direct notification to Building Control: Submit plans and pay fees before starting work

- Competent person scheme: Use registered electricians who self-certify their work

- Third-party certification: Have qualified inspectors test and certify completed work

Building Control fees vary by local authority but typically range from £150 to £500. These costs should be factored into your project budget from the planning stage. Some councils offer reduced fees for minor electrical work.

Notification exemptions exist for like-for-like replacements and certain minor works. However, adding new circuits or extending existing ones usually requires notification. When in doubt, contact your local Building Control department for clarification.

Failure to notify Building Control can result in enforcement action and difficulties selling your property. Insurance companies may also refuse claims for work that doesn’t comply with building regulations.

Obtaining Electrical Installation Certificates

Electrical Installation Certificates provide formal documentation of installation safety and compliance. These certificates are legal requirements for notifiable electrical work. They serve as proof that your installation meets current safety standards.

The certification process involves comprehensive testing by qualified personnel. Certificates must be issued by electricians holding appropriate qualifications and registrations. DIY installations typically require third-party testing and certification.

Required documentation includes:

- Electrical Installation Certificate (EIC) for new installations

- Minor Electrical Installation Works Certificate (MEIWC) for additions

- Periodic Inspection Report (PIR) for existing installation assessments

- Test results schedules showing all measurement values

- Circuit charts identifying all circuits and protective devices

Certificates must include specific technical information about your installation. This includes details of protective devices, cable types, and test results. All IP rated fittings and weatherproof components must be properly documented.

Keep certificates in a safe place with other property documents. Future buyers, insurance companies, and Building Control may request these documents. Digital copies provide useful backups for important certification paperwork.

Periodic inspection requirements apply to electrical installations in outdoor buildings. These inspections typically occur every 10 years for domestic installations. Commercial or rental properties may require more frequent inspections.

Proper certification isn’t just about compliance – it’s about ensuring your family’s safety and protecting your property investment for years to come.

The certification process may identify minor defects requiring attention before certificate issue. Address these issues promptly to avoid delays and additional costs. Most problems involve loose connections or inadequate earthing arrangements.

Maintenance and Troubleshooting Your Lighting System

Once your lighting system is operational, establishing a maintenance routine protects your investment and prevents costly repairs. Regular care ensures your outdoor building remains safely lit whilst extending the lifespan of all electrical components. A well-maintained system also helps you identify potential issues before they become serious problems.

Proper maintenance involves more than just changing bulbs when they fail. You’ll need to monitor electrical connections, test safety devices, and keep weatherproof seals in good condition. This proactive approach saves money and maintains the safety standards required for outdoor electrical installations.

Regular Inspection and Cleaning Schedules

Create a systematic inspection routine to keep your lighting system in optimal condition. Monthly visual checks help you spot obvious problems like damaged cables or loose fittings. These quick inspections take just a few minutes but can prevent major issues from developing.

Start your monthly inspection by examining all visible wiring for signs of damage, wear, or rodent interference. Check that junction boxes remain securely sealed and weatherproof. Look for any discoloration around electrical connections, which might indicate overheating or moisture ingress.

Clean light fittings every three months to maintain optimal illumination levels. Dust and debris reduce light output significantly, especially on LED panels and strip lights. Use a soft, dry cloth for most cleaning tasks, ensuring power is switched off beforehand.

Annual deep inspections require more thorough testing of safety systems. Test your RCD protection devices using the built-in test button every six months. This simple check ensures these critical safety devices will operate correctly if needed.

| Inspection Frequency | Tasks to Complete | Safety Considerations | Expected Duration |

|---|---|---|---|

| Monthly | Visual cable inspection, fitting security check, weatherproof seal examination | Switch off power before touching fittings | 15-20 minutes |

| Quarterly | Light fitting cleaning, switch operation testing, cable route inspection | Use dry cleaning methods only | 30-45 minutes |

| Bi-annually | RCD testing, earth continuity checks, electrical connection tightening | Qualified electrician may be required | 45-60 minutes |

| Annually | Complete system testing, insulation resistance measurement, certification renewal | Professional electrical testing recommended | 2-3 hours |

Common Problems and Repair Solutions

Most lighting system problems fall into predictable categories that you can often resolve yourself. Flickering lights typically indicate loose connections or failing LED drivers. Tighten all accessible connections first, then check if the problem persists.

When your RCD protection device trips repeatedly, this signals a genuine electrical fault that requires immediate attention. Don’t simply reset the RCD without investigating the cause. Common culprits include moisture in junction boxes or damaged cable insulation.

Never ignore a tripping RCD – it’s protecting you from potentially dangerous electrical faults that must be identified and corrected before normal operation can resume.

Gradual light level reduction usually indicates LED degradation or accumulated dirt on fittings. Clean the fittings first, as this often restores full brightness. If cleaning doesn’t help, individual LED modules may need replacement.

Moisture ingress problems require immediate action to prevent electrical hazards. Check all weatherproof seals and replace any that show signs of deterioration. Remember that water and electricity create dangerous combinations that demand prompt professional attention if you’re unsure about repairs.

- Flickering lights: Check connections and LED driver condition

- Complete light failure: Test fuses, circuit breakers, and power supply

- Intermittent operation: Examine switch contacts and cable joints

- Reduced brightness: Clean fittings and check for LED degradation

- RCD tripping: Investigate electrical faults before resetting

Upgrading and Expanding Your System

Your lighting needs may change over time, requiring system modifications or expansions. Adding extra lights to your existing installation is usually straightforward if you planned adequate capacity initially. Check your consumer unit has spare ways available for additional circuits.

When upgrading to more efficient LED technology, ensure your existing wiring can handle the new load characteristics. Modern LED systems often require different control methods compared to traditional lighting, particularly for dimming applications.

Smart lighting upgrades offer enhanced control and energy monitoring capabilities. These systems integrate with existing wiring but may require additional control modules and network connections. Plan these upgrades carefully to maintain electrical safety standards.

Major system expansions might trigger Building Control notification requirements, especially if you’re adding significant electrical load. Consult with a qualified electrician before undertaking substantial modifications to ensure compliance with current regulations.

Always maintain detailed records of any modifications or upgrades you make. Future maintenance becomes much easier when you have accurate documentation of your system’s configuration and component specifications.

Conclusion

Proper lighting installation transforms your shed, summerhouse, or log cabin into a valuable extension of your home. These outdoor spaces become functional areas for work, hobbies, and relaxation throughout the year.

The investment in quality lighting pays dividends through increased property value and enhanced usability. Your outdoor building becomes accessible during darker months and evening hours. This extends the practical life of your structure beyond daylight limitations.

Safety remains paramount throughout any electrical project. Part P compliance ensures your installation meets current UK regulations and protects your family. Professional certification provides peace of mind and satisfies insurance requirements.

Whether you chose solar panels, mains electricity, or low-voltage systems, regular maintenance keeps your lighting performing optimally. Simple cleaning schedules and periodic inspections prevent costly repairs and extend system lifespan.

Your newly illuminated outdoor building offers years of enhanced functionality. Evening workshops, garden parties, and quiet reading spaces become possible with reliable lighting. The careful planning and installation work creates lasting value for your property and lifestyle.

Remember that complex electrical work benefits from professional expertise. Qualified electricians ensure complete safety and regulatory compliance while often proving more cost-effective than DIY mistakes.

FAQ

Do I need to notify Building Control when installing lighting in my shed or summerhouse?

Yes, under Part P of the Building Regulations, you must notify Building Control for most electrical installations in garden buildings. This includes mains-powered lighting systems and new electrical supplies. However, simple replacements of existing fittings or battery-operated systems typically don’t require notification. It’s always best to check with your local authority before starting work to ensure compliance.

What’s the difference between IP ratings for outdoor lighting fittings?

IP ratings indicate protection levels against moisture and dust ingress. For garden buildings, you’ll typically need IP44 minimum for general areas (protected against water splashing), IP54 for more exposed locations (dust-protected and splash-proof), and IP65 for areas with direct water exposure (completely dust-tight and protected against water jets). Choose higher ratings for better long-term reliability.

Can I install mains electricity in my log cabin myself, or do I need a qualified electrician?

Whilst competent DIYers can undertake some electrical work, installing a new electrical supply to your log cabin typically requires a qualified electrician. This includes running cables from your main property, installing consumer units, and making connections to the mains supply. However, you can usually install light fittings and switches yourself once the main electrical supply is professionally installed.

How far can I run electrical cables from my house to my garden building?

The maximum practical distance depends on cable size and electrical load. For typical shed lighting, you can run 2.5mm² cable up to about 30 metres, whilst 4mm² cable can extend to 50 metres or more. Beyond these distances, voltage drop becomes significant, and you may need larger cables or alternative solutions like solar power. Always calculate voltage drop for your specific installation.

What are the best LED strip lights for illuminating a wooden shed?

For wooden sheds, choose IP65-rated LED strip lights with aluminium channels for heat dissipation and protection. Cold white (4000K-6500K) provides excellent task lighting for workshops, whilst warm white (2700K-3000K) creates a more comfortable atmosphere. Look for strips with good colour rendering (CRI 80+) and ensure they’re suitable for the operating temperature range in your shed.

Are solar-powered lights reliable enough for year-round use in the UK?

Modern solar lighting systems can provide reliable illumination throughout the year when properly sized and positioned. However, performance reduces during winter months due to shorter daylight hours and lower sun angles. For consistent lighting, choose systems with lithium batteries, oversized solar panels, and LED lights with motion sensors to conserve power during low-light periods.

What safety equipment do I need when installing electrical systems in my summerhouse?

Essential safety equipment includes insulated tools, voltage testers, safety glasses, and non-conductive ladders. Always use a multimeter to verify circuits are dead before working on them. Wear appropriate clothing and ensure you have adequate lighting whilst working. Most importantly, always isolate power at the consumer unit and test that circuits are dead before starting any electrical work.

How do I calculate the power requirements for my garden building lighting?

Calculate total wattage by adding up all your planned light fittings, then add 20% for future expansion. For example, six 10W LED downlights plus two 5W strip lights equals 70W total, plus 20% gives 84W. This helps determine cable sizes, circuit protection, and whether your existing electrical supply can handle the additional load without requiring upgrades.

What’s the most cost-effective way to light a small garden shed?

For occasional use, battery-powered LED lights or solar panels with rechargeable batteries offer the most cost-effective solution. For regular use, a simple mains-powered system with LED downlights controlled by a basic switch provides excellent value. Avoid over-specifying – a few well-positioned lights often provide better illumination than many poorly placed ones.

Do I need RCD protection for lighting circuits in my log cabin?

Yes, RCD protection is mandatory for all electrical circuits in garden buildings under current UK regulations. This provides life-saving protection against electrical faults and earth leakage. The RCD should be rated at 30mA for personal protection and can be installed either at your main consumer unit or as part of a dedicated garden building consumer unit.

How do I create weatherproof entry points for electrical cables?

Use proper weatherproof glands or cable entry systems designed for outdoor use. Drill holes at a slight downward angle from inside to outside to prevent water ingress. Seal around the gland with appropriate sealant and ensure cables have a drip loop before entering the building. Never simply poke cables through holes without proper weatherproof protection.

Can I use smart lighting controls in my outdoor building?

Absolutely! Smart switches, motion sensors, and timer controls work excellently in garden buildings. Choose devices rated for the temperature range and humidity levels in your building. WiFi-enabled smart switches allow remote control and scheduling, whilst PIR sensors provide automatic lighting for security and convenience. Ensure your WiFi signal reaches the building reliably for smart features to function properly.