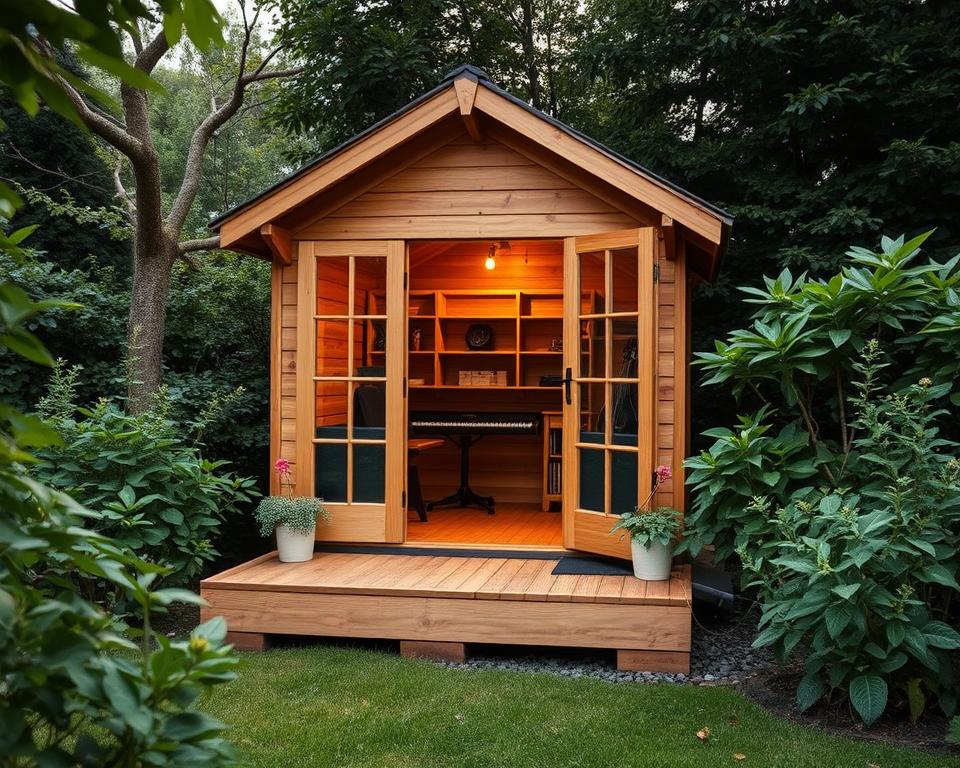

How to Make a Garden Music Shed for Practice and Recording

Many musicians dream of a dedicated space to create and record. An outdoor shed offers a fantastic solution. This type of studio provides isolation from household noise and distractions.

This comprehensive guide details the process of building a functional music room. It covers everything from initial planning to final touches. The aim is to create an environment with excellent soundproofing.

Whether converting an existing structure or building from scratch, this resource provides essential steps. It helps musicians establish a professional-quality space for their craft. The result is a personal studio right in the garden.

Inhaltsverzeichnis

Key Takeaways

- Creating a dedicated space for music practice and recording is achievable.

- An outdoor shed provides excellent isolation from household activities.

- Proper soundproofing is crucial for both internal acoustics and neighbourly relations.

- This guide offers a step-by-step approach to planning and construction.

- The project can be tailored to various budgets and skill levels.

- Careful consideration of location and materials ensures a successful outcome.

Introduction to Your Garden Music Shed

The concept of a detached music facility in one’s garden addresses multiple practical challenges simultaneously. These specialised structures provide musicians with the ideal environment for focused creative work.

Overview of Garden Music Sheds

Purpose-built garden studios represent a sophisticated solution for acoustic requirements. Unlike converted interior rooms, these structures can be designed from inception with proper sound management in mind.

The separation from the main residence creates natural acoustic isolation. This fundamental advantage makes garden sheds particularly effective for loud instruments and recording sessions.

Benefits of a Dedicated Music Space

A standalone studio offers psychological benefits that enhance musical productivity. The dedicated space creates a professional mindset, improving concentration during practice.

These structures maintain household harmony by containing sound effectively. Musicians can work at any hour without disturbing family members or neighbours.

Modern garden rooms can include full amenities like electricity and internet. This transforms a simple shed into a fully functional professional environment.

Planning and Designing Your Music Shed

The initial phase of creating a personal recording environment focuses on two critical aspects: location and resources. Thorough planning at this stage prevents costly mistakes later. A clear design vision guides the entire building process.

Assessing Space and Location

Choosing the right spot for the shed is paramount. The available area must be level and well-drained. Consider access for materials and proximity to power sources.

The size of the studio should accommodate all equipment comfortably. Good planning also involves checking local regulations. Natural features like fences can assist with sound management.

Budget and Timeframe Considerations

Financial design is as important as the physical one. The budget must cover the structure, soundproofing, and interior finishes. Always include a contingency fund for surprises.

The decision between a DIY project and hiring professionals hinges on money, time, and skill level. A realistic timeframe accounts for weather and material deliveries.

| Factor | DIY Approach | Professional Contractor |

|---|---|---|

| Cost Estimate | £500 – £3,000 | £1,000 – £4,000 |

| Time Commitment | Higher | Lower |

| Required Skill Level | Intermediate to Advanced | Minimal |

| Best For | Confident builders on a budget | Those seeking guaranteed quality |

This comparison helps musicians allocate their money and time effectively. A well-planned project ensures the new shed becomes a functional and inspiring studio.

How to Make a Garden Music Shed for Practice and Recording

Establishing clear functional needs forms the foundation of any successful music space project. This planning stage determines the entire direction of the design process.

Defining Your Requirements

Musicians should begin with an honest assessment of how the room will be used. Will it host acoustic instrument practice, electric instrument recording, vocal work, or full band rehearsals? Each application demands different acoustic considerations.

Equipment requirements must be catalogued early. This includes instrument storage, recording gear, and computer workstations. Proper planning ensures adequate electrical outlets and ergonomic positioning.

Designing with Acoustics in Mind

Acoustic principles should guide every structural decision. The design must balance soundproofing with internal acoustic treatment. These are complementary but distinct objectives.

Structural Insulated Panels (SIPs) provide excellent soundproofing while ensuring great acoustics. Additional acoustic panels can be added to improve performance further.

Window placement requires careful thought. Glass doesn’t lend itself as well to sound control as walls do. The design should incorporate flexibility for future modifications.

Professional consultation may benefit serious recording applications. Acousticians can help achieve precise frequency response and controlled reverberation times.

Building a Solid Structure and Base

Selecting the right construction approach significantly impacts acoustic performance. The choice between prefabricated and custom-built options affects both budget and soundproofing outcomes.

Prefabricated sheds offer rapid installation, often completed within days. This speed saves considerable time compared to traditional building techniques. However, their lightweight structure requires additional work for acoustic purposes.

Using a Prefabricated Shed vs Traditional Methods

Prefabricated units typically feature thin wall sheathing and suspended wood deck floors. These elements reduce initial costs but compromise sound isolation. The suspended floor creates air gaps that transmit vibrations.

Traditional construction allows for custom specifications from the outset. Builders can incorporate dense materials and proper stud spacing. This method provides superior quality but demands more time and investment.

“The foundation represents the most critical structural element. Proper preparation here determines the success of all subsequent acoustic treatments.”

When converting prefabricated sheds, the wood deck flooring must be removed. This exposes the concrete slab beneath, creating a solid base. The concrete should be level and properly sealed against moisture.

| Feature | Prefabricated Shed | Traditional Building |

|---|---|---|

| Installation Time | 1-2 days | Several weeks |

| Initial Cost | Lower | Higher |

| Wall Thickness | Thin sheathing | Customisable |

| Acoustic Performance | Requires upgrades | Built-in from start |

| Best For | Budget-conscious projects | Professional studio applications |

Both approaches can create a functional studio space. The decision depends on available resources and desired acoustic outcomes. A solid structure forms the foundation for all subsequent soundproofing efforts.

Soundproofing Fundamentals for Music Studios

Effective acoustic isolation rests on a foundational principle: mass. Without sufficient density, sound waves easily travel through barriers. This makes material selection a primary consideration for any project.

Thin, lightweight walls common in prefabricated structures offer minimal resistance. The solution lies in strategically adding mass. This approach significantly enhances soundproofing performance.

The Importance of Wall Mass and Material Choice

Denser materials block sound more effectively than lightweight alternatives. For existing thin walls, the goal is to increase their mass. A proven method involves applying multiple layers of dense sheet material.

Professional builds often use two layers of 16mm drywall on each wall surface. This creates substantial mass that impedes sound transmission. The principle is straightforward: more mass equals better soundproofing.

Incorporating Acoustic Panels and Insulation

While mass blocks sound, insulation absorbs vibrational energy within the wall cavity. Materials like mineral wool are highly effective. They work in tandem with mass layers.

Acoustic panels are then applied to interior surfaces to manage reflections. This combination of mass, insulation, and panels creates a comprehensive soundproofing system. Proper installation is crucial for success.

Airtight seals are non-negotiable. Gaps around new drywall must be filled with backer rod and acoustic caulk. This attention to detail ensures shed soundproof quality meets professional standards.

Enhancing Shed Walls, Floor, and Ceiling

The complete sound isolation system depends on treating walls, floors, and ceilings as interconnected elements. Each surface contributes to overall acoustic performance. A systematic approach ensures no weak points compromise the soundproofing effort.

Adding Layers and Mass to Shed Walls

Enhancing shed walls begins with adding mass through multiple layers. Starting with salvaged plywood on exterior surfaces creates a solid base. Interior drywall layers follow, installed with careful sealing techniques.

Each new layer should offset previous seams to distribute stress evenly. This staggered approach prevents sound leakage paths. The method transforms thin walls into effective acoustic barriers.

Sealing Gaps for Effective Soundproofing

Gap sealing represents the most critical aspect of practical soundproofing work. Even small unsealed cracks can reduce performance significantly. Meticulous attention to detail is essential.

The junction between walls and floor requires particular focus. All corners should be sealed with acoustic caulk before installing flooring. This helps prevent sound transmission between interior and exterior spaces.

Specialist underlayment materials create effective soundproofing for floors. Installed directly onto the concrete slab, they form a barrier against impact noise. The layered approach creates a complete acoustic envelope for the studio.

Incorporating Advanced Acoustic Treatments

Beyond basic soundproofing, specialised materials offer superior control over acoustic performance. These advanced treatments address specific challenges in managing sound transmission and internal reflections.

Each product serves a distinct purpose within the overall acoustic strategy. Understanding their individual functions ensures they work together effectively.

Utilising Mass-Loaded Vinyl and Acoustic Foams

Mass-loaded vinyl is a dense, flexible material that adds significant mass without bulk. It is particularly effective for shed soundproof applications where space is limited. The vinyl installs easily by cutting to size and fixing to surfaces.

Acoustic foam panels manage internal acoustics rather than blocking sound. They absorb reflections, reducing flutter echo and controlling reverberation. This improves the clarity of the sound within the space.

Spray Foam and Fibreglass Insulation Options

Spray foam insulation expands to seal tight gaps and crevices. It creates an effective barrier against air leaks. DIY kits are available from retailers like Home Depot or B&Q.

Adding fibreglass batt insulation over spray foam provides supplemental acoustic absorption. It is crucial to wear protective gear as fibreglass can irritate skin. This combination enhances the overall soundproofing performance.

Together, these materials control sound waves and reflections. They transform a basic structure into a professionally treated acoustic environment.

Practical Soundproofing Solutions for Doors and Windows

The functional requirements of access and natural light create inherent soundproofing complications. These openings represent the most vulnerable points in any acoustic barrier system. Effective treatment requires specialised approaches beyond standard wall construction methods.

Proper sealing techniques transform ordinary openings into effective acoustic barriers. The goal is to maintain functionality while significantly reducing sound transmission.

Weather Stripping and Acoustic Seals

Weather stripping around the door frame creates the first defence against sound leakage. Compression seals activate when the door closes, eliminating gaps that allow noise to pass. This simple solution dramatically improves overall acoustic performance.

Door sweeps or drop seals address the problematic threshold gap at the bottom. Automatic drop mechanisms provide superior performance compared to fixed alternatives. Acoustic caulking beneath the sill completes the permanent seal.

Installing Soundproof Window Inserts

Windows present fundamental challenges as glass transmits sound more readily than dense walls. Soundproof window inserts offer practical solutions by creating secondary glazing. The air gap between existing glass and the insert substantially improves isolation.

Alternatively, acoustic glazing with laminated construction provides effective sound control. Customised shutters that close during sessions offer maximum isolation when needed. These methods prevent sound transmission while maintaining natural light options.

Customising Your Shed Interior for Optimal Acoustics

Finalising the interior transforms the structure into a professional creative environment. This stage focuses on comfort, functionality, and fine-tuning the acoustic properties of the space. Careful attention to detail here elevates the entire studio experience.

Proper electrical installation is fundamental. It requires sufficient outlets for all equipment and dedicated circuits for sensitive recording gear. Lighting must provide excellent illumination without generating fan noise.

Lighting, Ventilation and Security Considerations

Ventilation maintains air quality during long sessions. Acoustically baffled systems or heat recovery ventilators provide fresh air while minimising sound leakage. This is essential for a comfortable room.

Security is paramount for protecting valuable instruments. Burglar alarms and mortice locks offer robust protection. CCTV systems provide an additional layer of security for the shed.

Floor coverings serve a dual purpose. Thick underlay and carpet contribute to soundproofing and improve internal acoustics. They also add warmth, making the studio usable year-round.

Finishing Touches and Personal Customisations

Plants offer a natural touch. Placing small trees or climbing plants around the area provides extra sound buffering. A living roof on a flat-roofed shed is an attractive, eco-friendly option that reduces noise transmission.

The final thing is acoustic fine-tuning. Positioning acoustic panels based on the room‘s response optimises sound. This may require some experimentation for the specific space size.

| Feature | Purpose | Key Benefit |

|---|---|---|

| Dedicated Circuits | Power sensitive gear | Prevents electrical noise |

| Baffled Ventilation | Maintain air flow | Preserves acoustic isolation |

| Mortice Locks | Enhance security | Protects valuable equipment |

| Acoustic Carpet | Floor treatment | Absorbs sound and adds warmth |

“The final layer of customisation is where the room truly becomes your own. It’s the balance of technical performance and personal comfort that creates an inspiring studio.”

Maximising the Potential of Your Music Shed

Taking a garden building to its ultimate level involves integrating advanced acoustic principles with thoughtful aesthetics. This approach ensures the structure functions as a top-tier creative space.

A room within room construction method offers the pinnacle of acoustic isolation. This design creates a separate interior structure, completely detached from the outer shell.

Specialised mounts prevent vibration transmission. This conversion is ideal for professional recording, where external noise must be eliminated.

Integrating Functional Design with Aesthetics

The visual appeal of the shed soundproof studio is as important as its acoustic performance. Exterior finishes should complement the garden.

Landscaping can soften the building’s presence. This thoughtful design makes the soundproof studio shed an attractive garden feature.

Inside, the room benefits from careful planning. Adequate space for the inner room is crucial for a successful room within room setup.

“A well-executed room within room design provides an acoustic environment that rivals professional facilities, all within the convenience of one’s garden.”

This advanced building technique requires significant time and a high skill level. The investment yields exceptional quality and control over sound waves.

Future expansion should be considered during the initial design phase. This foresight ensures the soundproof room can adapt over time.

| Component | Primary Function | Key Consideration |

|---|---|---|

| Inner Framework | Structural independence | Must not contact outer walls or floors |

| Isolation Mounts | Vibration decoupling | Specialised acoustic hardware |

| Air Gap | Sound barrier | Sufficient width is critical |

| Material Density | Mass addition | High mass for improved soundproof performance |

The final thing is to balance technical performance with personal comfort. This creates an inspiring and highly functional shed soundproof studio.

Conclusion

Converting an ordinary outdoor building into a functional recording space delivers substantial creative benefits. This comprehensive guide has outlined the essential steps for a successful shed conversion project.

Whether undertaking a DIY approach or hiring professionals, proper soundproofing remains crucial. Attention to detail in wall construction, sealing gaps, and treating openings ensures effective noise containment.

The investment of money and work yields a professional-quality studio that serves musicians for years. A well-executed soundproof shed provides the ideal environment for focused creative work.

Following these principles transforms any garden shed into an exceptional music studio. The conversion process creates a dedicated space where musical creativity can flourish undisturbed.

FAQ

What are the primary benefits of a dedicated garden music shed?

A dedicated garden music shed offers a sound-isolated space for practice and recording, preventing noise disturbance. It provides a private, creative environment separate from the main house, enhancing focus and productivity for musicians.

How does soundproofing differ from acoustic treatment?

Soundproofing aims to prevent sound from entering or leaving a space, using mass and sealed construction. Acoustic treatment manages sound quality within the room, using panels and foam to control echoes and reverberation.

Is a building permit required for a garden music shed?

A> Planning permission requirements vary by local council. Generally, sheds under 2.5 metres in height and not used for sleeping accommodation may fall under permitted development rights. Always check with the local authority.

What is the most critical element for effective soundproofing?

The most critical element is creating an airtight seal. Even small gaps can significantly compromise soundproofing performance. Attention to detail around doors, windows, and wall joints is essential.

Can an existing garden shed be converted into a music studio?

Yes, existing sheds can be converted. However, the existing structure’s strength must be assessed to support added mass for soundproofing, such as extra wall layers and insulation.

What is the “room within a room” design?

This advanced construction method involves building an isolated inner room inside the shed’s outer shell. It is highly effective at stopping sound transmission but requires more space and a higher budget.

Are specialised acoustic doors necessary?

A> While not always essential, standard doors are a weak point. For high sound isolation, solid core doors with weather stripping and acoustic seals are recommended to block noise leakage effectively.

How important is ventilation in a sealed music shed?

Ventilation is crucial for air quality and comfort. Acoustic ventilation systems are available that allow fresh air circulation while minimising sound leaks, ensuring a usable environment.